Martin Engineering’s N2® remote monitoring system – launching at Hillhead 2022

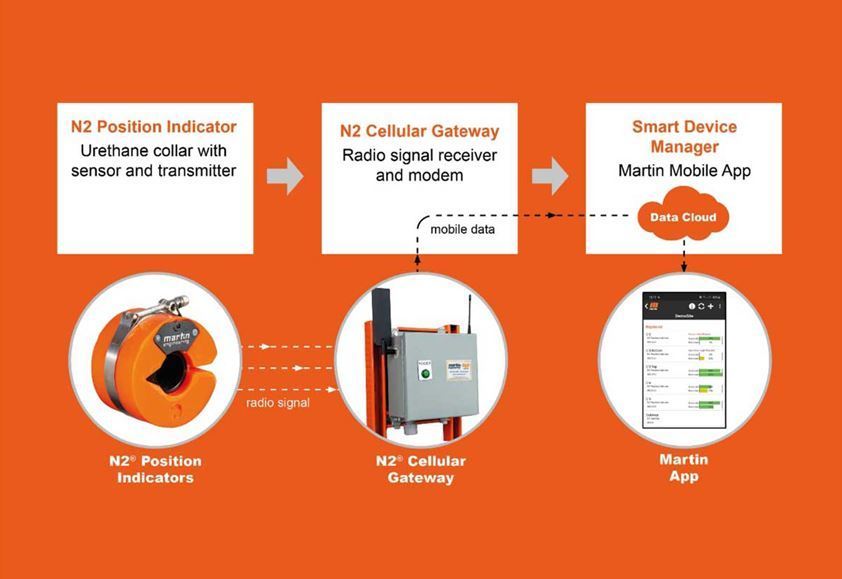

16.06.2022Martin Engineering is launching its innovative N2® remote monitoring system for conveyor belt cleaners at Hillhead. Designed for any belt cleaner using a polyurethane blade, the N2 Position Indicator (PI) system tracks belt cleaner performance and tells users when servicing is required via an intuitive cloud-based mobile app or desktop dashboard.

© Martin Engineering

N2 allows maintenance managers to keep on top of belt cleaner performance, eliminating needless inspection visits, reducing human exposure to moving conveyors and helping to increase production uptime.

After extensive research, development and trials, N2 is now available across Europe, Middle East, Africa and South Asia, having recently met all the requirements to achieve European CE Marking. Robert Whetstone, Vice President for Martin Engineering’s EMEAI region, said: “Our new N2 system is a game-changer that combines tried and tested technologies into one easy-to-use package so users can monitor their conveyor belt cleaners remotely. “With this smart yet simple upgrade, the technology does the legwork, providing real-time data on each belt cleaner blade to give an early indication of when servicing is needed. In the meantime, plant managers can be confident that material carryback, spillage and build-up is being controlled by the belt cleaner so they can keep the plant running to maximise productivity.”

© Martin Engineering

By tracking the individual performance and status of each belt cleaner, N2 PI delivers continuous, real-time feedback and eliminates guesswork. The detailed historic data also provides a maintenance log so service dates can be tracked and wear rates calculated. The result is an improved return on belt cleaner investments plus the ability to budget and forecast for essential replacement parts. Replacements can also be scheduled for just-in-time delivery helping users to better manage their inventory.

Development of the N2 PI has involved extensive technical research, as well as long-term customer trials at major material processing facilities in more than 10 countries worldwide. In the UK the system has been delivering results for more than 12 months at the country’s largest lime production plant, operated by Singleton Birch.

Stuart Howden, Engineering Manager at Singleton Birch, who has overseen the UK trials from the start, said: “Martin Engineering’s N2 Position Indicator is a clever system that eliminates the need for repeated visits to each conveyor belt – we will never need to go back to doing regular physical inspections of all our belt cleaners. With more than 90 conveyors across our production site, the ability to monitor our belt cleaner blades remotely is a massive advantage. Supporting Martin Engineering on the technology side are two trusted Amazon Web Services (AWS) ‘Internet of Things’ partners. The result is a fully automated, seamlessly integrated and secure cloud-based system that delivers super-reliable connectivity.”

Stand RA19