Hyundai complements programme with two articulated dump trucks

30.06.2022The Hyundai Construction Equipment adds two designs of dump trucks to its rapidly expanding line of heavy construction and grounding equipment. The HA30A and HA45A dumpers, with an estimated load of 28 and 41 tons respectively, are comparable to the large crawling of Hyundai and wheel loaders.

Hyundai HA30A und HA45A

Hyundai HA30A und HA45A

© Hyundai Construction Equipment Europe

The two dump trucks are the first visible result of a new partnership between Hyundai Construction Equipment Europe (HCEE) and Hyundai Doosan Infracore (HDI), launched after the purchase of Doosan by Hyundai Heavy Industries Group. HCEE and HDI now operate as separate Hyundai Genuine units while maintaining their independent management structures and sales networks.

Continued integration of technology for both companies will open up natural partnerships in research and development, design, procurement and manufacturing, thereby enhancing the benefits of the whole group. Together, HCEE and HDI will develop integrated platforms for miners and wheel loaders and at the same time boost their own sales by selling additional equipment.

The Hyundai HA45A has an estimated load of 41 tons

The Hyundai HA45A has an estimated load of 41 tons

© Hyundai Construction Equipment Europe

Some of the features:

· Even the distribution of weight and the chassis shape behind the slope provides stability by placing more load in the center of the machine, resulting in a lower center of gravity.

· The backbone exchanger of the bogie for better ground clearance and first-class tension

· The innovative concept of transmission leads to a shorter front frame of the chassis

· The propeller ring placed near the front axle of the support link provides a uniform distribution of weight from the front to the back and across the front axle during orientation.

· Large cabinet with easy access from the front of the machine

Specified dump truck

Hyundai Building Materials enters the defined hauler market with two models combining certified, innovative design and technology with high productivity and excellent mobility on site. Targeted in the 30 and 45 ton market segments, the HA30A and HA45A are built on the concept of a six-wheel-drive permanent car; they have different front and rear lock locks and a mid-range lock that can be self-locking for higher operation and tension in a hard area.

The transporter has a shorter chassis structure for better maneuverability, with a sliding rear frame and a front-mounted variant connected to the ZF transmission for a shorter front part of the front frame. This results in a smaller radius of turn on the market and better stability. Hydropneumatic suspension suspension on the front axle also helps to drive smoothly and ensures maximum stability in harsh ground conditions. The punching ring is arranged in front of the pivot point of the chassis, which leads to greater stability and traction in every driving situation due to the distribution of weight even on the front wheels. Thanks to the even weight distribution, the driver can use locks variants with a closing value of only 45 ° and thus maintain the vehicle on all front wheels even during operation.

The two rear axles work with a concurrent structure, the difference of one channel and two internal gear drivers on each side of the throttle. These parallel reduction gears rotate a total of around 40 °, thus allowing for better ground contact to be maintained in the hard surface by increasing the excitation of the rear axle. One central difference increases the ground clearance under the dumper. The HA30A and HA45A are set as standard and fully hydraulic controller as well as electronic engine brakes. In this way, most disk brakes running in an oil bath can achieve a long service life of up to 15 000 hours. Water-powered parking brakes make the machine stand still. Dumpers come with a diameter, axis protector and “Body Over Center of Gravity” feature to assist operators when steering and working in a difficult area.

The chassis part of the rear slope distributes the load evenly between the front and rear axles. The HA30A has a body volume of 16.8 m3, which increases to 17.8 m3 with a rear gate installed. The large HA45A provides a body capacity of 24.4 m3; and the rear gate is 26.0 m3. Both bodies can be ignited voluntarily by engine exhaust gases so that there is no freezing material or sticks during operation at low temperatures. Interior lining wear plates are available for use on hard rock.

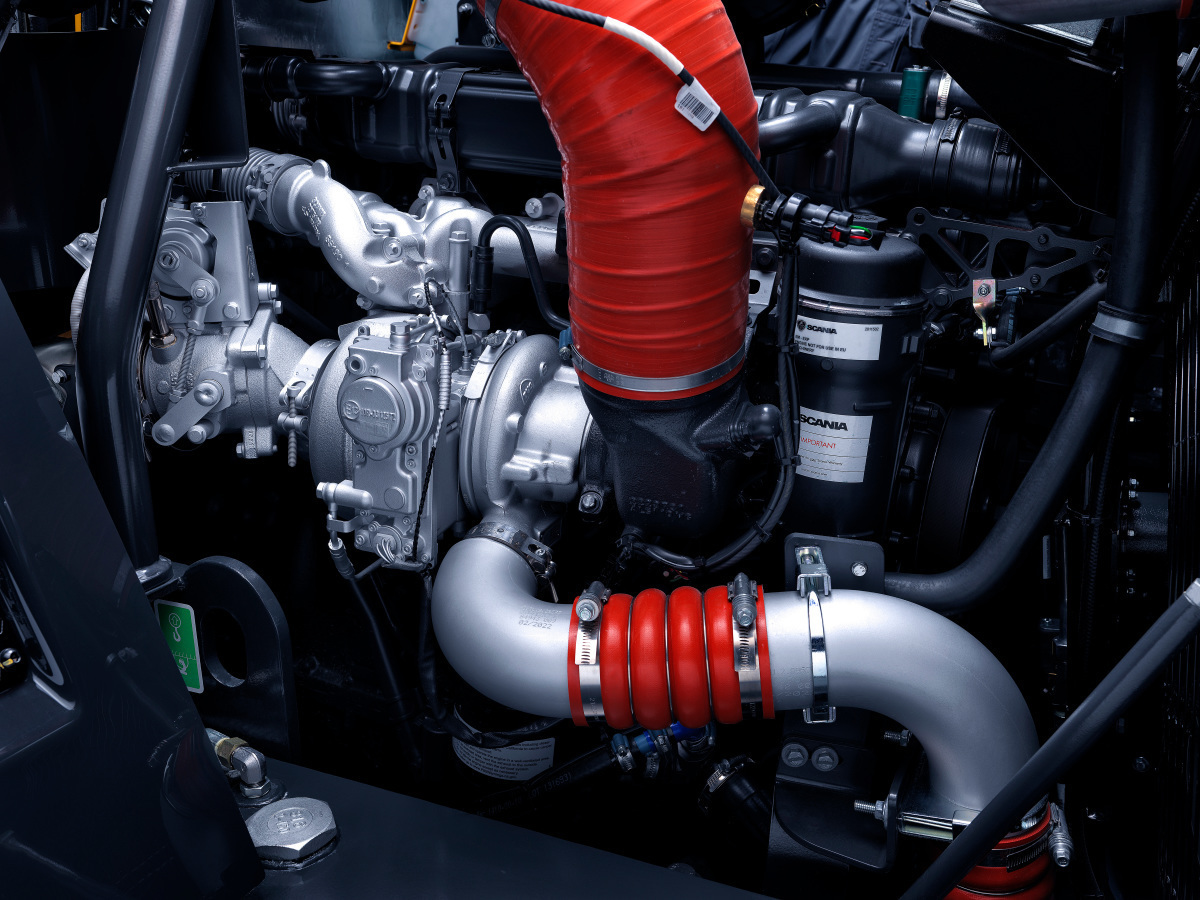

Hyundai has selected Scania diesel-powered engines to power both carriers, which meet EU Stage V

Hyundai has selected Scania diesel-powered engines to power both carriers, which meet EU Stage V

© Hyundai Construction Equipment Europe

Proven power

Hyundai has selected Scania diesel-powered engines to power both carriers, which meet EU Stage V. HA30A emissions standards using a five-cylinder, 9.3-liter turbo diesel diesel. DC9, which develops 375 hp and torque of 1876 Nm. The large HA45A is a 12.7-liter six-cylinder diesel engine DC13 in use, which develops a maximum of 500 hp and 2476 Nm of torque.

Both engines are connected by an eight-speed ZF automatic transmission with integrated rear axles. The torque converter with lockup in both gears reduces fuel consumption and increases efficiency. Fuel, AdBlue (diesel greenhouse liquid) and conventional automatic lubricating system are readily available from the ground level for increased safety of the work site. The engine cover bends forward to access filters and filling parts, with the full taxi design also moving towards the rear of the carrier for access and maintenance access.

Hyundai’s Hi MATE telematics tracking system using GPS satellite technology has been included as a standard to reach even the most inaccessible areas of construction and quarrying in the world. It allows customers to monitor productivity, fuel consumption, system notifications and maintenance status remotely, reduce unplanned time and improve shipping usage.

Cabin detail

Cabin detail

© Hyundai Construction Equipment Europe

Comfort and protection

In addition to the largest taxi in the market with ROPS / FOPS protection, Hyundai distributors offer well-designed controls that are easily accessible from the high-performance driver’s seat. Specifications include MP3 and Bluetooth compatible audio, USB charging station, rotating safety pins and foot station. Inside the taxi there are plenty of storage space, optional cooling / heating box and 12V telephone sockets and other operator equipment. Both models have full air conditioning as usual, and the taxi has an internal noise level of 72 dB (A) only for maximum comfort throughout the working day.

Entrance detail

Entrance detail

© Hyundai Construction Equipment Europe

The slope hood provides excellent visibility for the front part of the carrier, and there are sliding windows and knives on the sides of the seat. The comprehensive monitoring panel provides integrated loading testing to prevent excessive loading and productivity recording. The diagnostic functions are integrated into the monitoring system and the operator can monitor fluid and discharge oil levels away from the cupboard. The upper diameter ensures that the carrier is safely operated within its limits, while the rear camera with large mirrors provides a better round view below you. miner or should be rearranged in the bending column.