High intensity magnetic separation at UK Mining Conference

05.06.2024Bunting is one of the world’s leading designers and manufacturers of magnetic separators, metal detectors and electrostatic separators. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, and Berkhamsted, both in the United Kingdom.

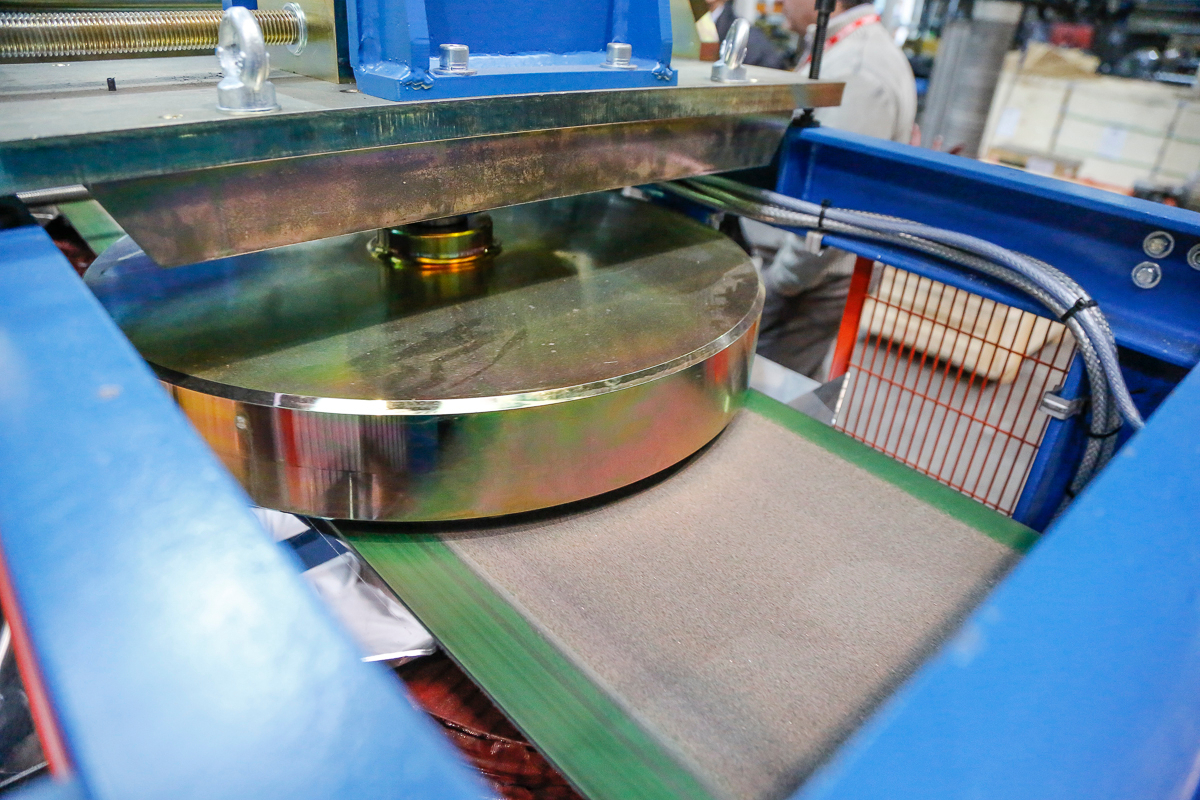

Magnetic Disc Separator processing beach sands

Magnetic Disc Separator processing beach sands

© Bunting

High-profile delegates including investors, brokers, operators, and the mining supply chain attend the two-day conference, held at the historic Princess Pavilion in Falmouth in Cornwall.

The recent rise in mining activity in Cornwall reflects the importance of sourcing valuable metals such as lithium, copper, tin, tungsten, cobalt, as well as minerals to increase food production, and provide housing and infrastructure for an ever-growing population.

Papers presented at the conference highlight the opportunities to responsibly extract the abundance of metals and minerals in the UK, recap on the work undertaken so far, and illustrate the potential investment opportunities that lie ahead.

Magnetic separation, in many forms, plays a key role in most mining operations and mineral processing plants. Larger Overband Magnets, such as the compact and lightweight ElectroMax, work alongside Metal Detectors to remove and detect tramp metal and prevent damage to crushers and screens.

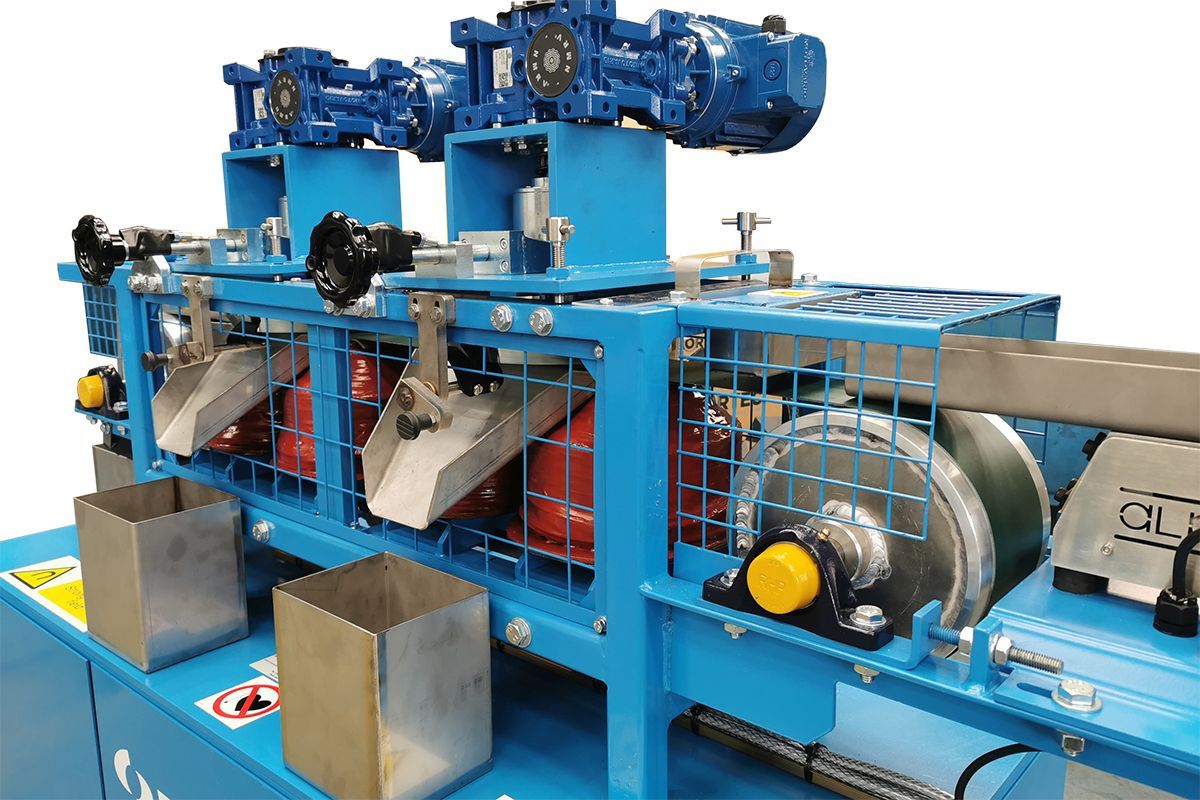

The minerals test laboratory at Bunting's Customer Experience Centre

The minerals test laboratory at Bunting's Customer Experience Centre

© Bunting

In the more specialised area of mineral processing, Bunting is one of the world-leading suppliers of high-intensity magnetic separators including the Rare Earth Roll Separator, Magnetic Disc Separator, and Electromagnetic Filter, as well as ElectroStatic Separators. Bunting’s team of experienced mineral processing engineers are continuously conducting controlled material tests at the Customer Experience Centre in Redditch/UK. The results form the basis of flowsheet design and equipment selection, maximising recovery and purity.

Bunting’s team on the stand at the UK Mining Conference in Cornwall includes Phil Tree, Professor Neil Rowson, and Michael Allen.

“Due to complex geological and mineral characteristics, successful extraction of valuable materials often involves many processing stages that includes magnetic separation and electrostatic separation,” explained Phil Tree, Bunting’s Applications Manager. “With decades of mineral processing experience, we are able to provide guidance and support to mining companies, advising on best practice and the optimum separation technology. We are looking forward to speaking with mining companies at the conference.”