Haver & Boecker Niagara to showcase engineering strength at AGG1 with full-size portable plant

04.03.2025Haver & Boecker Niagara will display its engineering expertise with a full-size Niagara F-Class Portable Plant at World of Asphalt/AGG1 2025. Visitors at Booth 1344 at America’s Center Convention Complex in St. Louis will discover cutting-edge technology firsthand, as Haver & Boecker Niagara highlights the latest innovations designed to maximize efficiency, durability and performance in aggregates operations.

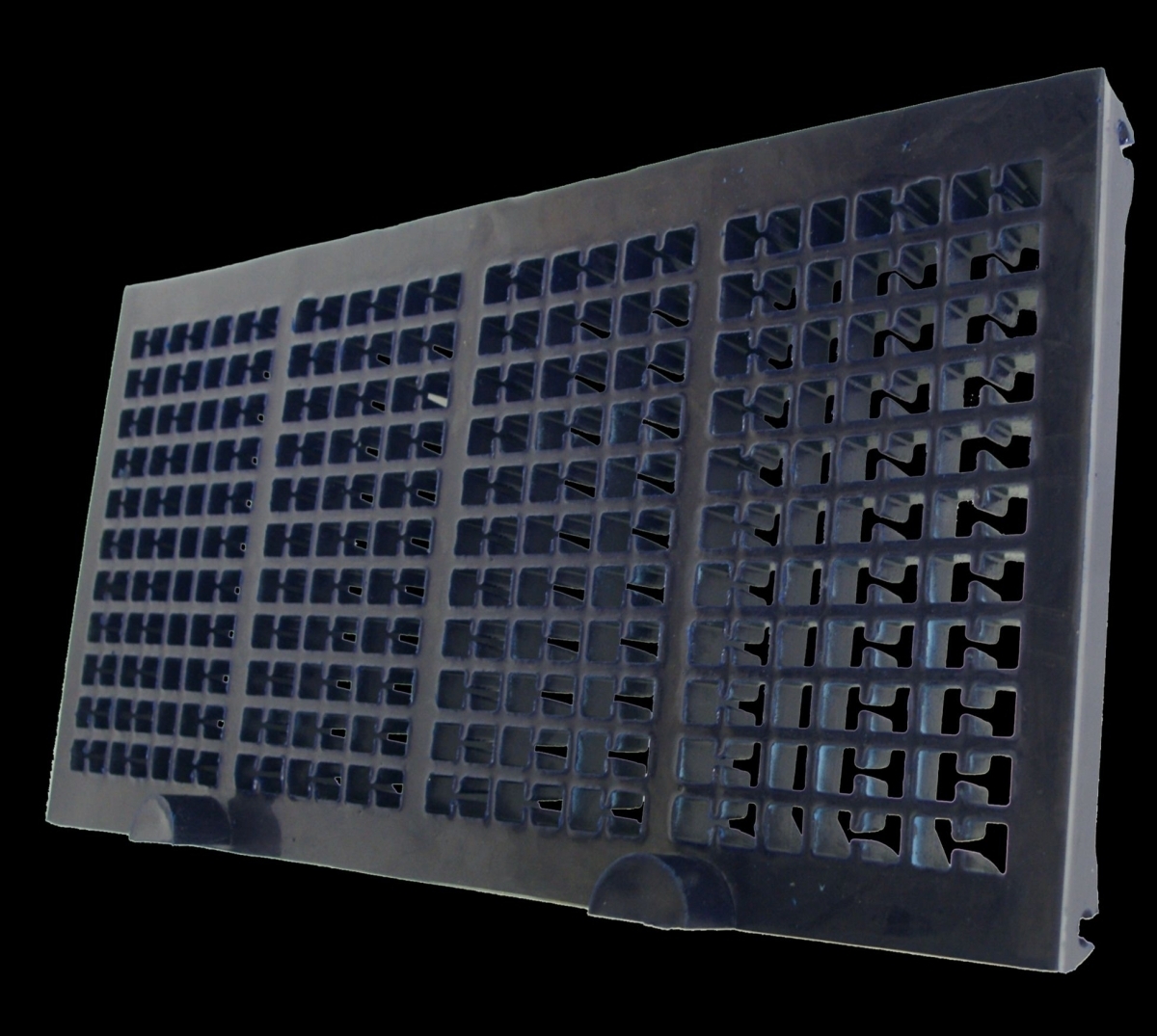

The Niagara F-Class Portable Plant from Haver & Boecker Niagara features a double-eccentric shaft assembly that maintains constant g-force during startup, shutdown and extreme conditions, including overloading and surging

The Niagara F-Class Portable Plant from Haver & Boecker Niagara features a double-eccentric shaft assembly that maintains constant g-force during startup, shutdown and extreme conditions, including overloading and surging

© Haver & Boecker Niagara

“We wanted to flex our muscles at this year’s AGG1 and ‘wow’ showgoers by rolling in our full-size F-Class Portable Plant,” said Julie Andras, Haver & Boecker Niagara director of marketing. “It will be an exciting focal point for attendees, and we’re excited to talk with them about the machine’s features that can take their aggregates operation to the next level.”

The Niagara F-Class Portable Plant features a hydraulic system providing setup in less than 30 minutes. The vibrating screen can be lowered in less than five minutes for easy screen media changeouts

The Niagara F-Class Portable Plant features a hydraulic system providing setup in less than 30 minutes. The vibrating screen can be lowered in less than five minutes for easy screen media changeouts

© Haver & Boecker Niagara

The F-Class Portable Plant on display will feature a double-eccentric shaft assembly that maintains constant g-force during startup, shutdown and extreme conditions, including overloading and surging. Its custom-built chassis holds the vibrating screen and periphery equipment, such as crushers or conveyors, to customize the plant depending on operational needs. The plant allows users to get it up and running quickly, with a hydraulic system providing setup in less than 30 minutes. It also offers easy maintenance as the vibrating screen can be lowered in less than five minutes for easy screen media changeouts. Inclined, circular motion technology uses gravity to help move material down the screen deck, reducing pegging as well as energy and horsepower requirements.

Haver & Boecker Niagara’s Pulse Diagnostics portfolio monitors the health of vibrating screens and identifies issues before they become critical, improving the productivity and proficiency of an operation

Haver & Boecker Niagara’s Pulse Diagnostics portfolio monitors the health of vibrating screens and identifies issues before they become critical, improving the productivity and proficiency of an operation

© Haver & Boecker Niagara

“Despite being longtime exhibitors at AGG1, we still feel a sense of excitement each year when the show comes around. It’s a great event to catch up with current and potential customers about their business, what’s been going well, what hasn’t and how we can help them improve their operation,” said Karen Thompson, president of Haver & Boecker Niagara’s North American and Australian operations. “This year, we have the exciting opportunity to present an educational seminar about diagnostics. And that, I’m sure, will be a big topic in the booth, too, as everyone wants to optimize their operational capabilities.”

Ty-Deck Ultra modular screen media offers a robust solution for aggregates operations seeking more sustainable options in applications requiring production increases combined with high abrasion resistance

Ty-Deck Ultra modular screen media offers a robust solution for aggregates operations seeking more sustainable options in applications requiring production increases combined with high abrasion resistance

© Haver & Boecker Niagara

Wilm Schulz, service manager at Haver & Boecker Niagara, will present the educational session, “Maximizing Equipment Productivity Through Diagnostics,” where he will discuss how diagnostics work with aggregates producers’ equipment. Schulz will also educate the audience about the differences between types of monitoring systems: point-in-time and continual.

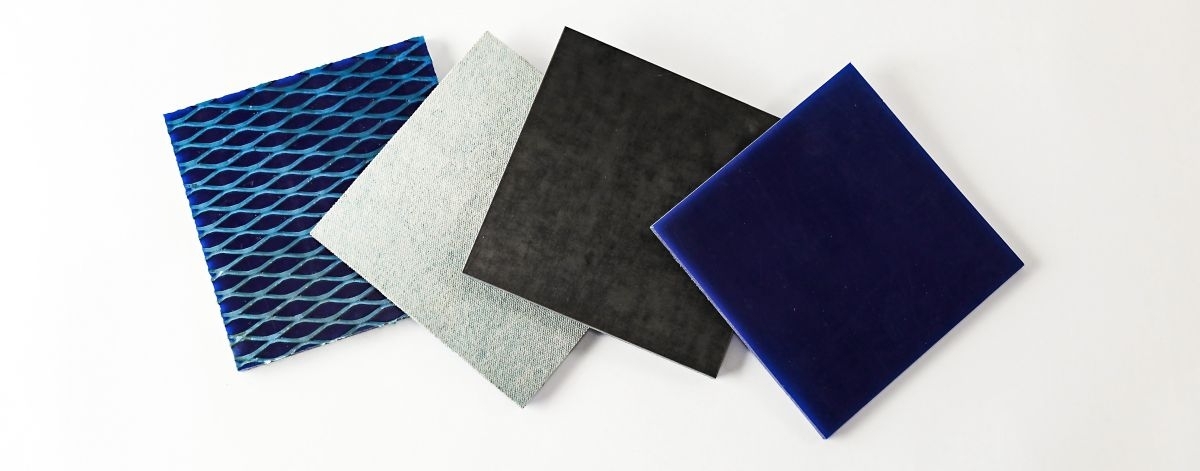

Rhino Hyde Blue liners can be custom-made with several different backings, including solid steel, plain, expanded metal, fabric and ceramic chip embedded

Rhino Hyde Blue liners can be custom-made with several different backings, including solid steel, plain, expanded metal, fabric and ceramic chip embedded

© Haver & Boecker Niagara

Experts from Haver & Boecker Niagara will discuss diagnostics solutions with booth visitors, as well. A pioneer in diagnostics technology, the company offers operations a robust suite of solutions. The Pulse Diagnostics portfolio – encompassing Pulse Vibration Analysis, Pulse Condition Monitoring and the Pulse Impact Test – monitors the health of vibrating screens and identifies issues before they become critical, improving the productivity and proficiency of an operation.

Showgoers can get an up-close look at Haver & Boecker Niagara’s diagnostics technology, download insightful brochures and view additional useful information with the company’s interactive kiosk. Haver & Boecker Niagara will also have samples of various types of its durable and innovative screen media, along with the company’s high-abrasion-resistant Rhino Hyde Liners.