Driving sustainable mining: CECE and industry leaders unite to advance CRMA goals

20.01.2025Almost one year after its creation and six months after CRMA enter into force, CECE invited policymakers and mining industry representatives and equipment manufacturers to discuss about the contribution of mining equipment and technology industry in reaching CRMA goals.

In his welcome address, CECE President Jose Antonio Nieto, citing the Draghi report, emphasised the importance of improved European raw materials production, diversification of suppliers (country) for raw materials and acceleration in the implementation of the CRMA. He highlighted that, although often neglected, the mining equipment and technology industry has a fundamental role as the enabler of a more efficient, safer, and sustainable mining industry and provider of the means to achieve the ambitious targets, particularly regarding extraction, set out in the CRMA. Finally he mentioned the leadership of the European mining equipment and technology industry in the global market and stressed on the importance of creating a demand for “green products” from consumers and industries to support mining projects with hight ESG standards.

Florian Anderhuber, Deputy Director General of Euromines, mentioned the ongoing raw materials transition driven by low carbon technologies and highlighted the good momentum created by the CRMA for the mining industry, citing updates in permit legislation in some Member States and more funding available for mining projects as examples. When asked what CECE Mining could do to support the European mining industry, he expressed his wish that new and more advanced technology will provide better information and data to support mining companies’ decisions thus reducing the risks of projects shutting down in the so called “valley of death” phase.

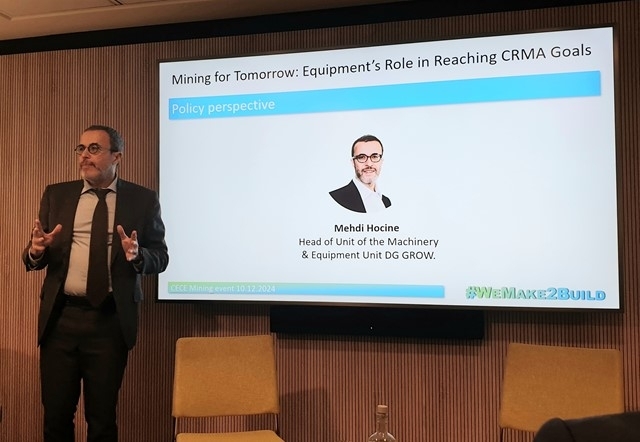

Mehdi Hocine, head of the Unit Machinery and Equipment at DG Grow (European Commission)

Mehdi Hocine, head of the Unit Machinery and Equipment at DG Grow (European Commission)

© CECE

Mehdi Hocine, head of the Unit Machinery and Equipment at DG Grow (European Commission), highlighted the role of machinery in achieving the 10 % goal for local extraction of raw materials included in the CRMA. On top of the Clean Industrial Deal that Commission is expected to approve within the first 100 days, the new EU Commission and Mr Hocine Unit intend to support the mining equipment industry by monitoring and if necessary closing some regulatory gaps in the internal market legislation, simplifying regulation and reducing red tape.

Susanne Norgren, Head of the Scientific Council at Sandvik, mentioned how mining practices and technology evolved in the last 80 years and presented the electrification journey of Sandvik which started in 2011. She then presented Sandvik’s raw material resilience strategy, based on 4 pillars integration along the value chain – citing the example of the company owning its own tungsten mine – substitution, recycling and performance improvement that allows to mine more with less resources.

Youssef Hnit, Hitachi Construction Europe, presented the ACE program which stands for Automation, Connectivity and Electrification. These goals should guarantee not only safe and productive mining but should also contribute to a high degree of automation and consequently autonomous operations. He encouraged an alignment of the whole industry to make sure the CRMA goals are achieved and stressed the importance of cooperation between mining companies and equipment manufacturers to ensure the successful technology adoption required to build a true net zero mining sector.

Albrecht Zuther, MD of Andritz Separation presented the technology of Andritz against the background of an increasing number of tailing ponds as result of more mines opening in the coming decades to supply the raw materials required by the green transition. In the past, several accidents with dam failure caused many victims in South America but also in Europe. Technology like the one proposed by Andritz, separates the solid fraction from the liquid component of mine tailings, allowing safer storage, reducing water usage and unlocking the possibility to further process the dried material to extract residual raw materials containing in it. Finally, Mr Zuther he hoped that the high EU quality and safety standards of European mining equipment will become the reference

Samar Adjdadi, Sales Manager EMEA & CIS for Becker Mining AG, introduced to the audience Becker’s concept for a “Mine of the Future”: a highly connected and automated environment that ensures high performance and safer operations. Next he highlighted the reputation for quality, reliability and safety of European made mining equipment in the markets he’s responsible for, something his company and other European OEMs should be proud of. On the safety side, he presented the benefits of proximity detections systems that contribute to reduce human and materials costs linked to collisions between equipment and personnel in underground mines.

Timo Sarvijärvi, Public Affairs Director Europe at Metso, described some of the biggest challenges for mining industry today ranging from less rich ore bodies, high risks due to low ROI predictability to lack of skilled workforce. Next he stressed on the importance of creating a demand for green products to support investments in mining projects with high ESG standards and invited EU and Member States to accelerate on mining permit procedures to reduce uncertainty around mining projects. In his closing statement he called for Europe to support its mining equipment and technology champions by allocating more funding to R&D, education and training.

Finally Riccardo Viaggi, Secretary General of CECE, stated that CECE will continue working with policymakers to remove obstacles that hamper member companies’ competitiveness. He closed the event by thanking audience and speakers and inviting them to visit bauma 2025 next April in Munich.