Design of new portable plant extends life of HSI crusher wear parts

16.12.2022Superior Industries says its brand-new Portable Sentry® HSI Closed Circuit Plant is equipped with the ability to process recycled concrete, reclaimed asphalt, and pit run materials into valuable salable products. From a single feed, owners and operators will be able to produce up to four unique products.

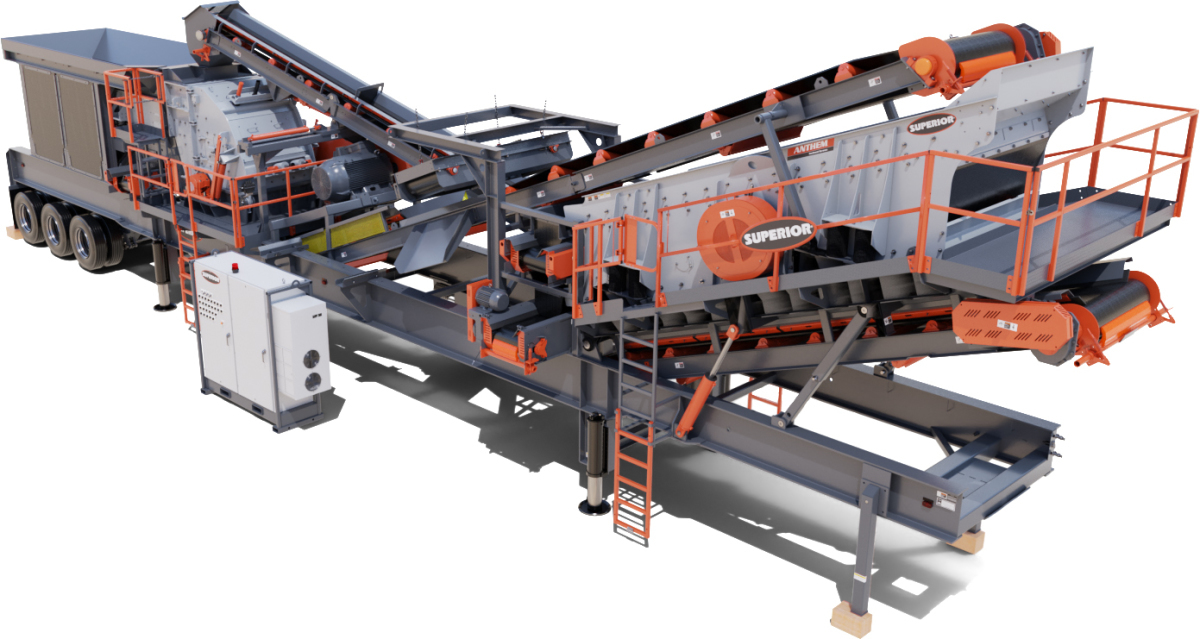

Superior’s new Portable Sentry® HSI Closed Circuit Plant

Superior’s new Portable Sentry® HSI Closed Circuit Plant

© Superior

The closed circuit crushing and screening arrangement includes a 4250 Superior brand Sentry® Horizontal Shaft Impactor (HSI). It’s fed by a 48 x 20 Intrepid Vibrating Grizzly Feeder, which is equipped with interchangeable grizzly cassettes (bars, fingers or punch plates) to accommodate multiple applications.

Additionally, a 2-deck Anthem® Inclined Screen screens up to three material sizes. Returning material is fed back to the HSI via a patent pending recirculating conveyor, which centralizes the feed for full utilization and extended wear life of the crushers blow bars. Onboard, the cross conveyors are universally designed to be interchangeable, which means owners invest in fewer conveyors since they can be mixed and matched throughout the plant.

“We’re a vertically integrated, single source designer and manufacturer of wheeled plants including all of the processing equipment, conveyors and components,” says Matt Voigt, the product manager for Superior’s portable plants. “This plant is 100% Superior, which allows us to fine tune and customize all the equipment and components for greater performance, improved portability, and easier maintenance.”

The plant is equipped to accommodate line power, but can also be outfitted with a diesel drive genset unit. Its transport weight, dimensions and axle configurations make it permissible for road travel throughout all of North America. Along with 250-tons of other products, Superior’s new Portable Sentry® HSI Closed Circuit Plant will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.