Breaking the blueprint

19.04.2021Digital technology allows organizations to collaborate earlier, forming new, more efficient, or safer ways of working. While its implementation is easier for uniform processes in bulk, things get trickier when working at a rarer size and scale. However, technology exists that can make planning a heavy lift project as simple as walking around site – months or years before it even exists. Mammoet World investigates.

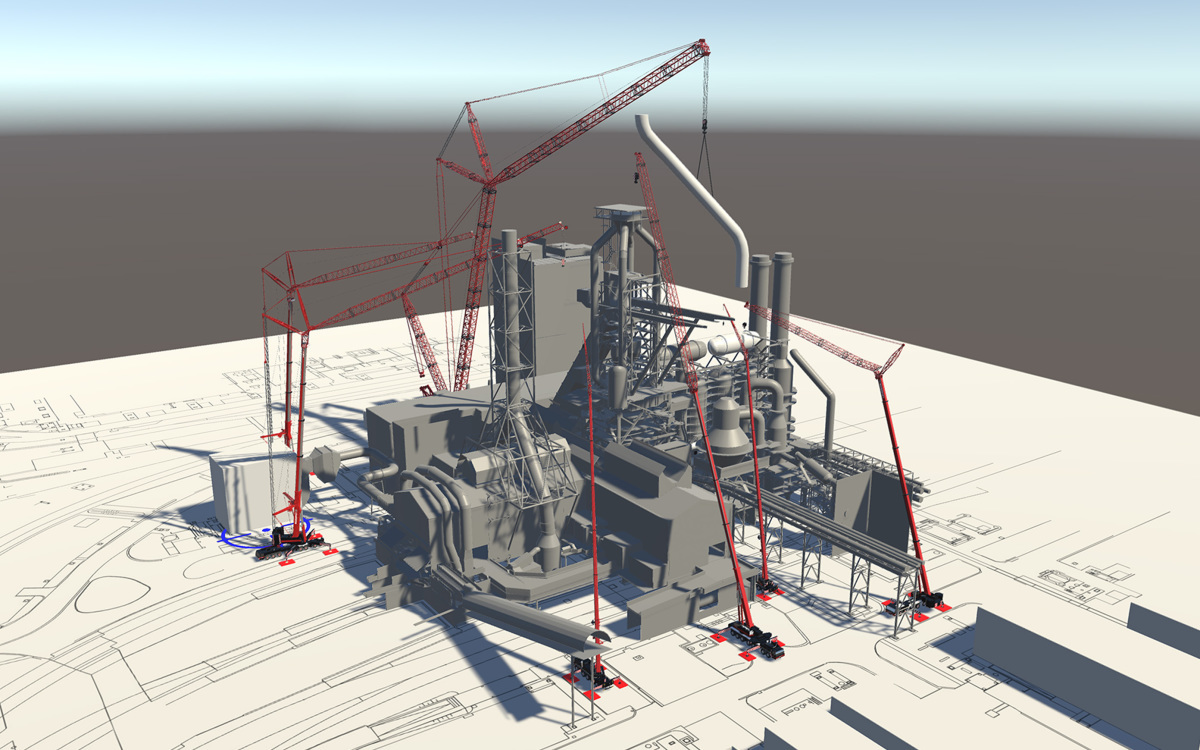

PTC50 crane within the Move3D platform

PTC50 crane within the Move3D platform

© Mammoet

The role of engineered heavy lifting has always been to support the incredible feats of others; by offering guidance on the possible and impossible. By establishing early on how loads can be lifted, transported or even divided, decisions can be made that pay out many times over throughout the life of a project.

The modern engineer has many tools at their disposal. LIDAR route surveys can establish whether roads have the necessary clearance, during the course of a single drive. Digital mapping integration can establish the shortest overall transport route. On site, load cells will calculate a module’s center of gravity to minute accuracy – clarifying what is stable and what is not. But things haven’t always been this good.

Forty years ago, lift preparations were a painstaking manual process, undertaken using the humble pencil by rows of engineers at drawing boards. Projects would be mapped out in meticulous detail; each image bespoke, uncontrolled and resource-hungry. Director of Engineering for Mammoet Europe, Leon van Tiel, takes up the story.

“Any heavy lifting or transportation project requires thorough, expert planning before equipment gets anywhere near to the project site. This planning stage is an important opportunity to discuss client requirements in detail in order to develop the most effective solution for the task in hand. Traditionally, two-dimensional (2D) technical drawings were used to communicate with customers as plans were developed and finalized.”

Although these were effective, the traditional ‘blueprint’ approach had its limitations. For example, the depth of information that can be communicated was restricted – literally. Specific views and key elements of the proposed work had to be prepared in advance and time taken to rework and revisit if the customer wanted to see a different perspective or phase.

Particularly where new or innovative methodologies were being proposed, a way to bring the project to life and allow the client to get a deeper understanding of things more quickly was sorely needed. Around thirty years ago, this first revolution in planning took hold.

“In the 1990s, Mammoet was the first heavy lifting company to develop and use a digital tool to accurately source and draw the most suitable crane in 2D project plans. At the time this was ground-breaking, in how all information about crane equipment and performance was stored within the program – allowing quick, accurate plans to be formed at the click of a button, rather than referring to multiple pages of load charts and calculations.”

3D CAD modelling – using static images – has been an important part of engineering planning for some time, but even it cannot offer the type of immersive, interactive project visualization that can help to improve on the traditional blueprint approach. Though computer-aided design is less wasteful of physical resources, it can still offer customers only a single viewpoint of a project at a time. It also provides no avenue to integrate heavy lift planning with the wider project – causing time to be wasted as engineers wander down impossible dead-ends.

Forming networks

During the last decade, digitalization has seen many industries using enhanced information modelling to give stakeholders better insights during the design and implementation of projects. In particular, industrial and energy businesses increasingly rely on technologies such as digital twinning to minimize how construction and maintenance work impacts site operations, and to optimize productivity.

In the construction sector, use of digital technologies has allowed our customers to plan around unstable ground or discoveries of historic or hazardous materials; to better connect projects and teams; and to improve the volume and quality of data being collected. So, Mammoet explored how the latest 3D technology – moving beyond CAD modelling – could help in communicating project plans and align more closely with our customers’ digitalization work.

There are multiple benefits to a 3D approach over the conventional 2D format. Complex projects can be communicated in a much clearer format, avoiding potential misinterpretation and increasing understanding about why a specific method has been selected.

Customers can interact directly with the 3D model to explore how different elements would work from multiple viewpoints and timestamps, prompting discussions that can be supported by these clear visualizations. Potential issues can be identified via a virtual tour of the site – and a plan to manage them developed earlier in the process than may otherwise have been possible.

Although the potential for 3D project visualizations has been recognized for some time, technology has been a barrier to its introduction. The processing power required to visualize complex heavy lifting and transportation work to a high standard, in real time – beyond conventional CAD applications – has not been widely available until recent years.

Smarter and safer

However, in 2018, Mammoet identified that the right technology was now available to make regular 3D project visualizations a reality. A team was formed to develop this exciting possibility and explore how it could be harnessed to help meet and exceed customer requirements. This project became known as Move3D and was led by van Tiel. “Move3D is a 3D engineering platform that combines business intelligence, such as crane charts, with Mammoet equipment and client data. It is independent from crane manufacturers and has been developed with the end-user in mind.”

The Move3D system complements customers’ own digital systems and methods. Information including LIDAR scans and point clouds, or third-party data such as satellite maps, can be easily incorporated into visualizations for accuracy and consistency with wider project planning. Data from the Move3D system can be exported for use within, for example, Building Information Modeling (BIM) tools, and can be communicated in a variety of forms.

“Offering this practical method to give our customers 3D visualizations of projects is an important way to present and discuss our plans in the simplest, clearest format possible. At the flick of a switch we can show them the details and complexities of our work – from any angle and at any point in the project,” said van Tiel. “Not only does this mean clients are able to get a more developed picture of how the work will happen, crucially it also gives us the opportunity to identify and discuss any pinch points – quickly addressing anything that might not be clear or may require changing.”

The Move3D system has already been used across a number of projects, including for BASF in Germany, with considerable success. Dirk Balzer, BASF Project Manager: “The 3D animation was a useful tool to precisely observe the restricted space conditions impacting on a heat exchanger replacement. Perhaps most impressive of all was that the live execution of the job matched the animation 100 %. We quickly recognized the advantages that Move3D could offer and were very impressed with how easy it made explaining the planned activities to all of our decision makers in BASF.”

Electric dreams

The system is now being rolled out across Mammoet’s global operations, but the current version is not likely to be the last. With clients adopting more sophisticated digital technology, Move3D will adapt to continue to offer the best possible visualization of a project as new techniques become available.

Mammoet now has a best-in-class platform that can evolve as required to continue offering the most effective support for project planning and workflow optimization. Van Tiel again: “It was important to us that Move3D offered the right compatibility with how our clients are using digitization in their own work. An exciting aspect of the system is the ability to offer visualizations in VR. This means that a client can ‘walk’ around the project and see for themselves how we will perform a move. There is even the possibility to put yourself in the cab of the crane to simulate the specific actions involved. We know this ability to view planned work in such detail will also have health and safety benefits – allowing potential issues to be identified and dealt with sooner in the process.”

Organizations across engineering, construction and maintenance disciplines are increasingly aware of the potential that digital transformation offers to discover efficient new ways of planning and delivering projects. Mammoet is proud to play a key enabling role in this process, using technologies such as Move3D to increase levels of productivity, cost-effectiveness and safety on site.