The new Outotec® Cooling Towers – High efficiency with strong environmental performance and safety

Outotec has launched a new series of cooling towers (Fig.) offering major environmental, safety and performance benefits in processes requiring efficient direct cooling, including zinc spent electrolyte cooling and copper solvent extraction gypsum removal and other uses. The Outotec® Cooling Towers offer increased cooling capacity as well as lower emissions to air.

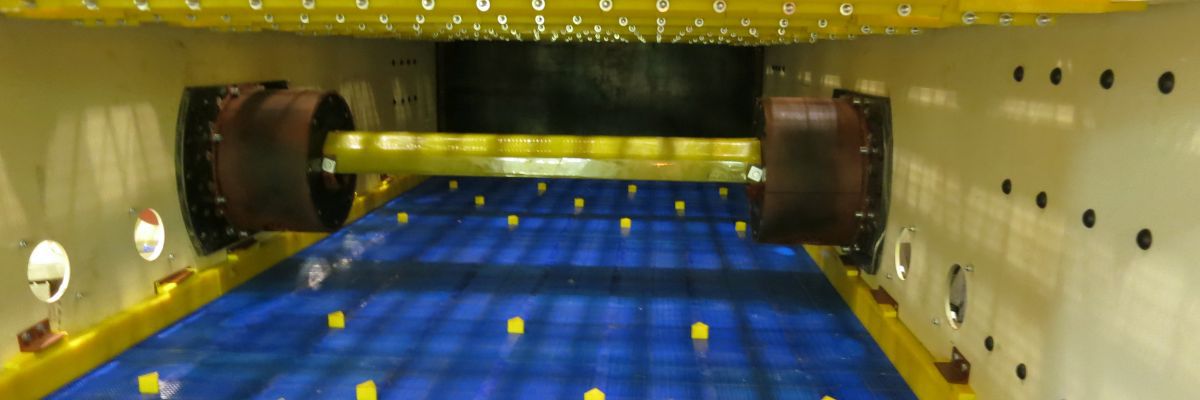

The most important change is that the air flows out of demisters horizontally, not vertically, as in conventional cooling towers. This allows for higher speed airflow in the demisters resulting in the ability to use more cooling air. In addition to the horizontal demister’s increased efficiency, the new technology’s careful nozzle placement ensures efficient droplet distribution and separation, reducing emissions to as low as 20 % of traditional cooling tower designs. The new structure and high efficiency fans also improve cooling air flow distribution inside the tower. Furthermore, the inflow of the air can be adjusted dynamically so that the out-flowing solution temperature can be controlled.