Pneumatic conveying systems in hygienic design

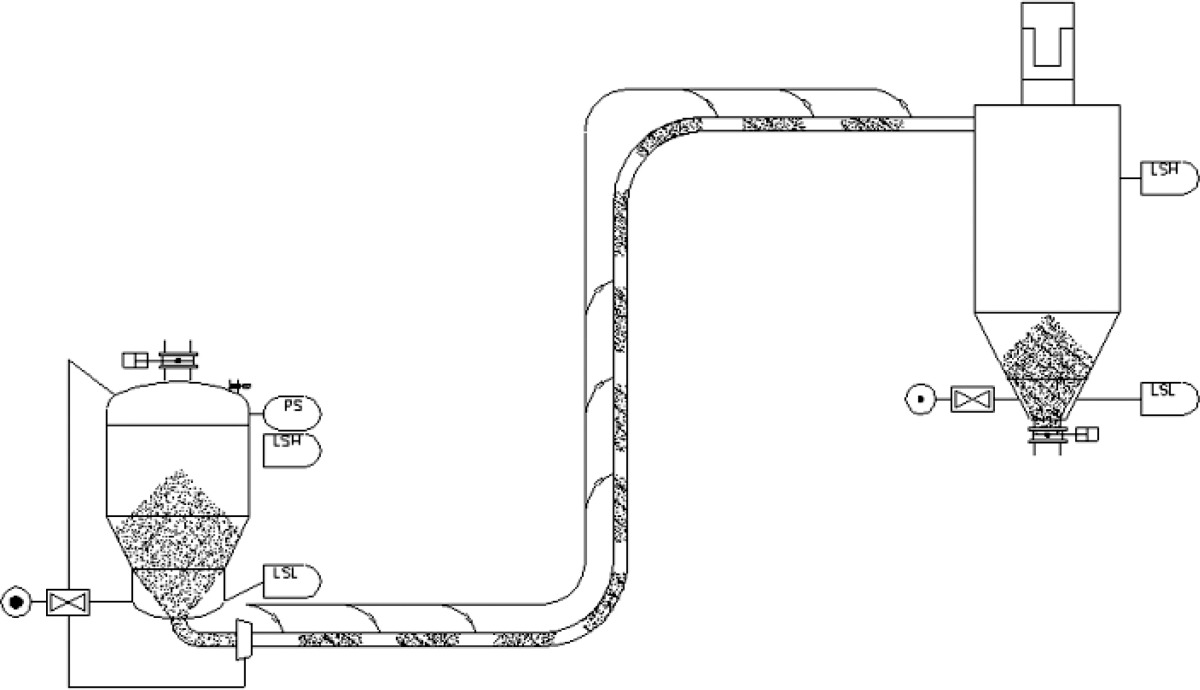

The solids solutions group has developed a new pneumatic conveyor in hygienic design complying with EU ordinances and directives (Fig.) and premièred this at Powtech 2010. The stainless steel conveyor with a suitable alloy fulfils HACCP and GMP requirements, has no dead zones, is easy to clean, CIP capable and piggable. The mounting connections have no dead spots, the seals are FDA-approved, and the surfaces have a defined roughness height. The conveyor line system with centred clamping rings is easy to dismantle; the material entry is designed as a disc valve free of dead spots.

Depending on the properties of the bulk solid conveyed, the conveyor is used in various pneumatic conveying processes, e.g. in dense phase pressure conveying, push conveying (also with bypass) or plug conveying with bypass, impulse valve and relay stations. In the latter case, the full pipe system is the gentlest low-velocity conveying system for sensitive and abrasive products.

S.S.T. Schüttguttechnik GmbH, Landsberg/Lech (D),

Tel.: +49 8191-3359-0, www.solids.de