Granite no problem for the Rammer 5011

A Rammer 5011 rock breaker has been successfully used to break extremely hard granite on a Kuala Lumpur residential development. The Rammer 5011 was able to meet the project’s requirements after other brands of breaker proved unequal to the taxing demands and challenges presented.

The excavation and site preparation for a residential housing development in Taman Connaught, Cheras, in Kaula Lumpur’s south-eastern suburbs, was recently undertaken by local civil engineering contractor, Crescendo Infra Sdn Bhd on behalf of a local developer. A proven earthworks, roads and infrastructure specialist, Crescendo Infra is a well-known, and respected contractor in the area, undertaking a wide variety of differing projects around Kuala Lumpur and the surrounding area.

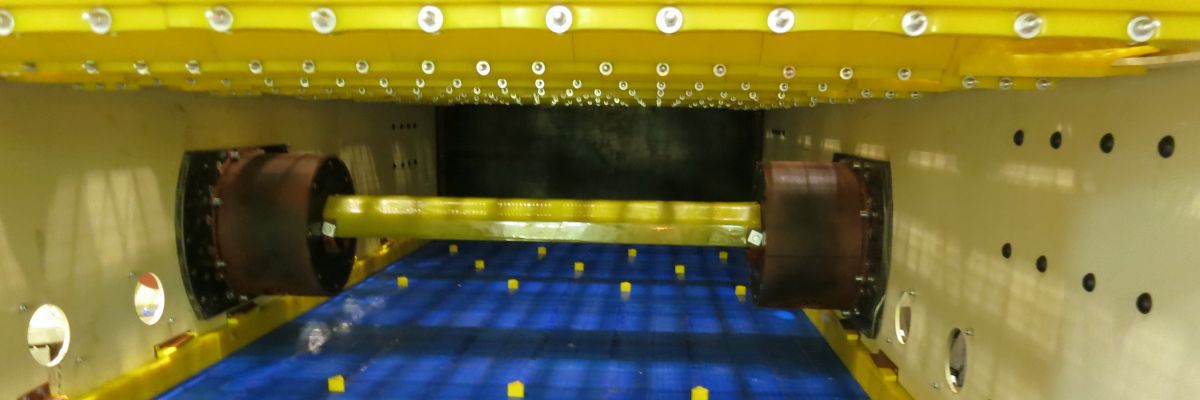

In order to deal with the extremely hard granite that was found in the locale, the company approached Power Ram, Malaysia’s Rammer breakers and attachments dealer. In order to undertake Crescendo Infra’s primary rock breaking, Power Ram brought in one of the latest Rammer breaker developments. Power Ram Director Ky Kok explained. “We brought in a Rammer 5011 breaker mounted on a 45 ton class Volvo E460 excavator. We were confident that this breaker, which features a long-stroke setting delivering a lower blow frequency, and is specifically designed for optimum breaking in very hard materials, would be suitable for this project.”

Ky goes onto explain how the material was successfully tackled by the Rammer 5011:“The granite on this job was so hard that we needed to pre-drill it before we could start breaking the rock. Even so, at first our penetration rates were quite slow, but as we proceeded with the job, they started to improve. By the end, we were achieving rates of 11-16 m3 every eight hours.” He adds; “It took us two and a half months to move around 1040 m3 of this very hard granite. We got there in the end, in what is a great example of how Rammer breakers are able to break rock that other makes can’t even touch!”

It is easy to see why the Rammer 5011 breaker succeeded on dealing with the exceptionally hard granite where other breakers failed as it has an operating weight of 4750 kg and is designed for carriers in the 43-80 ton class. Other key features that proved indispensable on the job include Rammer’s leading flexible operating principle. This means that stroke length and idle blow protection can be easily adjusted to allow the hammer to be better matched to the specific application at hand. Additionally improved hydraulic efficiency delivers greatly increased impact energy and higher blow frequency, giving an unmatched power-to-weight ratio.

What also proved to be vitally important to Crescendo Infra are the lower operating costs they experienced. This is achieved as Rammer’s VIDAT (vibration dampening tie rods) system provides improved reliability and minimizes downtime, while the industry’s most advanced sealing system and enhanced lubrication help to reduce operating costs

The 5011’s ability to vary stroke length allows it to be purpose-matched to individual applications and materials through the use of two simple working mode selectors located on the breaker itself. This was particularly apparent in dealing with the granite application in Kuala Lumpar. The long-stroke setting of the 5011 uses a lower blow frequency for optimum breaking of hard materials, such as granite ( and reinforced concrete foundations ), while its short-stroke setting delivers higher blow frequency, making it ideal for softer materials, such as limestone.

At the same time, an idle blow protection system allowed Crescendo Infra’s operator to easily adjust the working mode to provide protection against idle strokes. Further extending the working life of the 5011, it came fitted as standard with Rammer’s Ramlube II system, which uses a cartridge mounted on the hammer to automatically deliver optimum levels of lubrication for greater wear protection and longer service life. The unit is installed to the hammer's housing with a mounting plate and no external electric cables or hydraulic hoses are needed.

The new 5011 as used by Crescendo Infra also comes with Rammer’s Ramdata II service indicator as standard. This allows operators and service personnel to get information about the service interval status, service history and accumulated working history of their hammer. All of these features more than proved their worth allowing Crescendo Infra to successfully deal with the exceptional hard granite found.