Asphalt granulator buckets – asphalt crushing and recycling waste material

03.07.2024Simex CBA asphalt granulator buckets are specifically designed for the volumetric reduction of asphalt slabs deriving from road pavements demolition or other aggregates directly on site. The cylindric drum composed of interchangeable teeth is activated by direct-drive high-displacement radial piston motors.

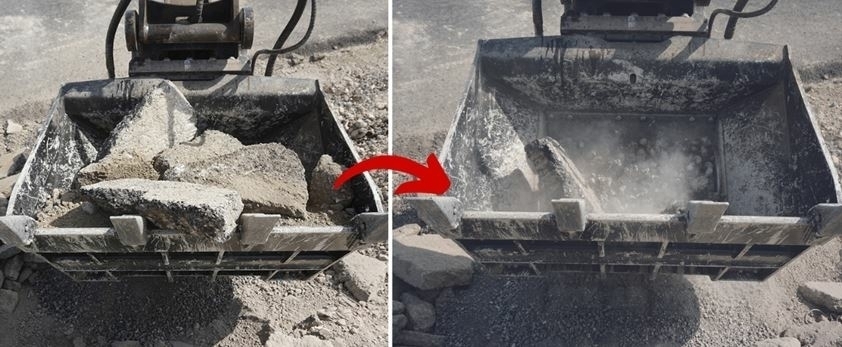

CBA asphalt granulator buckets are specifically designed for the volumetric reduction of asphalt slabs or other aggregates, directly on site, at a certifiable grain size

CBA asphalt granulator buckets are specifically designed for the volumetric reduction of asphalt slabs or other aggregates, directly on site, at a certifiable grain size

© Simex

CBA asphalt granulators are available in 3 models for excavators from 12 to 40 t and they are specifically designed for the volumetric reduction of asphalt slabs or other aggregates, directly on site, at a certifiable and measurable grain size.

The equipment features a cylindrical drum consisting of interchangeable teeth, driven by large displacement radial piston hydraulic motors, in direct drive.

Milling drum with interchangeable teeth (right) and configurable back-grid

Milling drum with interchangeable teeth (right) and configurable back-grid

© Simex

The rear grid determines the grain size of the material output and is available in several configurations, to meet the different characteristics required for the milled material by the regulations in force in various countries. The standard passing grid features holes of 25 mm diameter which produce a 0 to 20 mm output size of the crushed asphalt. Passing grids of different sizes are available on request – for example with holes for sizes between 0 to 25 and 0 to 40 mm. The result is a reclaimed asphalt pavement (RAP) with a certifiable and measurable granulometry.

Automatic system inverts the rotation of the drum in case of blocking, granting high productivity and avoiding downtimes.

Recycling of asphalt milling

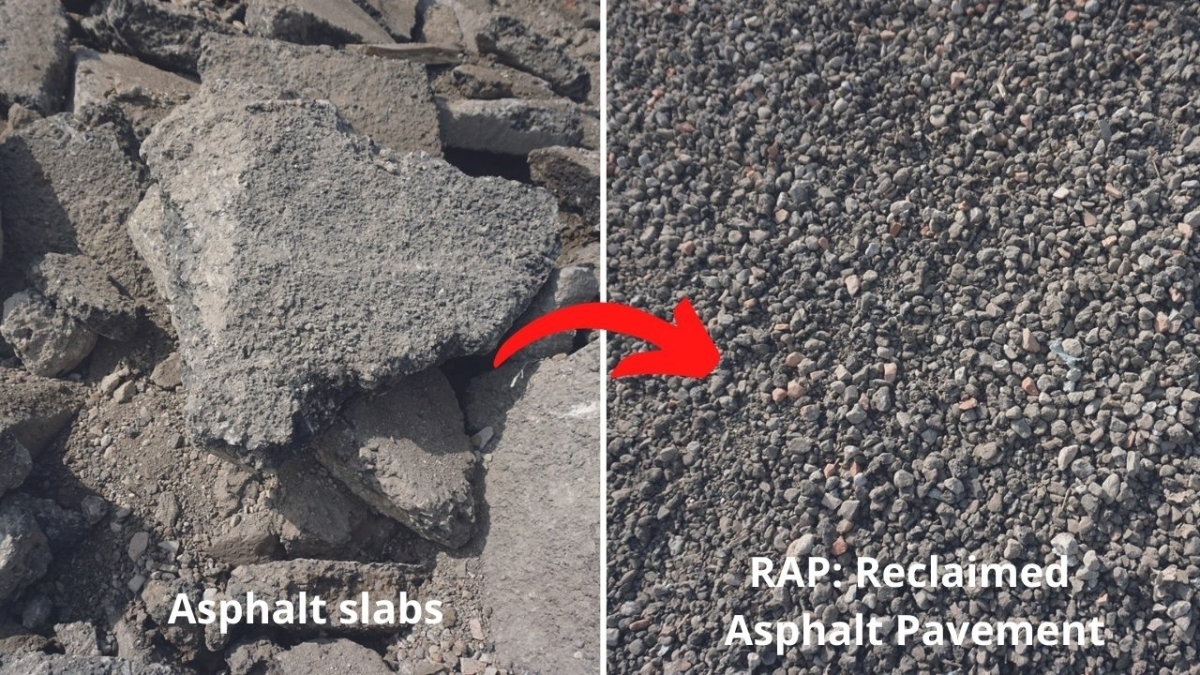

Simex has chosen to focus on the recycling of asphalt milling, more correctly called today bituminous conglomerate granulate by the legislation (called RA or RAP – Reclaimed Asphalt Pavement), beginning from its expertise in the field of crushing and screening waste materials from demolition.

CBA buckets is specialized in the recovery of milled asphalt material, classified in national regulations as RAP, Reclaimed Asphalt Pavement

CBA buckets is specialized in the recovery of milled asphalt material, classified in national regulations as RAP, Reclaimed Asphalt Pavement

© Simex

The circular economy of this sector

In the world of road maintenance and paving, as well as construction, the issue of recovering material deriving from demolition and scarification is becoming increasingly urgent, with the dual objective of combining environmental protection with economic savings.

© Simex

© Simex

Now, as never before, it is necessary to realize the sector features its own circular economy, particularly in regards to bituminous conglomerates: road paving can be recycled several times, in full compliance with the regulations in force. Almost 10 million tons of milled bituminous conglomerate are produced every year in Italy. Significant amount, which corresponds to approximately 18% of all waste from C&D (Construction and Demolition).

The granulator bucket has the dual advantage of combining reduced construction site costs and the possibility of reintroducing the RAP into the production cycle of new asphalt

The granulator bucket has the dual advantage of combining reduced construction site costs and the possibility of reintroducing the RAP into the production cycle of new asphalt

© Simex

Environmental protection

Cutting down the time and costs related to transport, minimizing the purchase of new raw materials, means optimizing the logistical and economic dynamics of your site, while keeping a watchful eye on the issue of environmental impact and the recovery of those materials which, subject to specific local regulations, could be considered a resource and no longer waste.

CBA buckets are not only used for processing asphalt

CBA buckets are not only used for processing asphalt

© Simex

CBA bucket features a milling drum that can easily process also other construction site aggregates such as bricks, concrete or tiles.