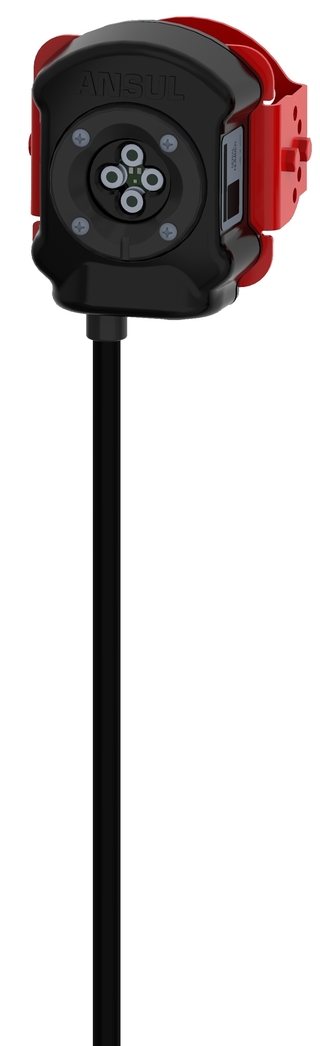

ANSUL® CHECKFIRE 210 Quad Infrared Detector provides faster detection and response to mining vehicles fires

07.11.2024Johnson Controls launched the new ANSUL® CHECKFIRE 210 Quad Infrared (QIR) Detector for mining vehicle fire protection. When used alongside linear heat detection systems, the CHECKFIRE 210 QIR Detector uses infrared technology to help increase the speed of fire detection and response on mobile mining equipment.

© Johnson Controls

© Johnson Controls

High-value, mission-critical mining vehicles often operate in harsh conditions with open, exposed hazard areas. Even a minor fire incident can take these vehicles off the job and interrupt business continuity. To minimize the severity of fire damage and increase peace-of-mind on the worksite, this new ANSUL quad infrared technology can detect flames within seconds, even across a wide range of operating conditions like smoke, dust, fog and varying temperatures.

“Our team specifically engineered the robust CHECKFIRE 210 QIR Detector for harsh real-world mining environments with new features that help accelerate the speed of flame detection and suppression response,” said Kristin Ryczek, global product manager, Vehicle Fire Suppression Systems, Johnson Controls. “With customers in mind, we designed the new QIR detector to seamlessly integrate and communicate with existing ANSUL CHECKFIRE 210-D fire detection control systems, so better performance is just a simple upgrade away.”

The ANSUL CHECKFIRE 210 QIR Detector leverages infrared technology to detect hydrocarbon flames faster than other detectors on the market, and to reduce the possibility of false discharges. The detector features an innovative latching alarm signal that quickly identifies which detectors have been activated. This information helps save critical time and effort needed for physical vehicle inspection during and after a fire event.

The CHECKFIRE 210 QIR system includes the new quad infrared detector, interface modules, installation bracketing and a dedicated optical test unit. The QIR detector has been tested to meet or exceed operational standards for the mining industry, including:

- FM 5970 and FM 3260

- ActiveFire listed – AS 5062

- Industry operational testing, vibration profile and pressure wash resistance

- In-field customer testing and feedback requirements

- Enhanced OEM mining industry standards