ANDRITZ launches AI-supported polymer dosage system for reduced OPEX

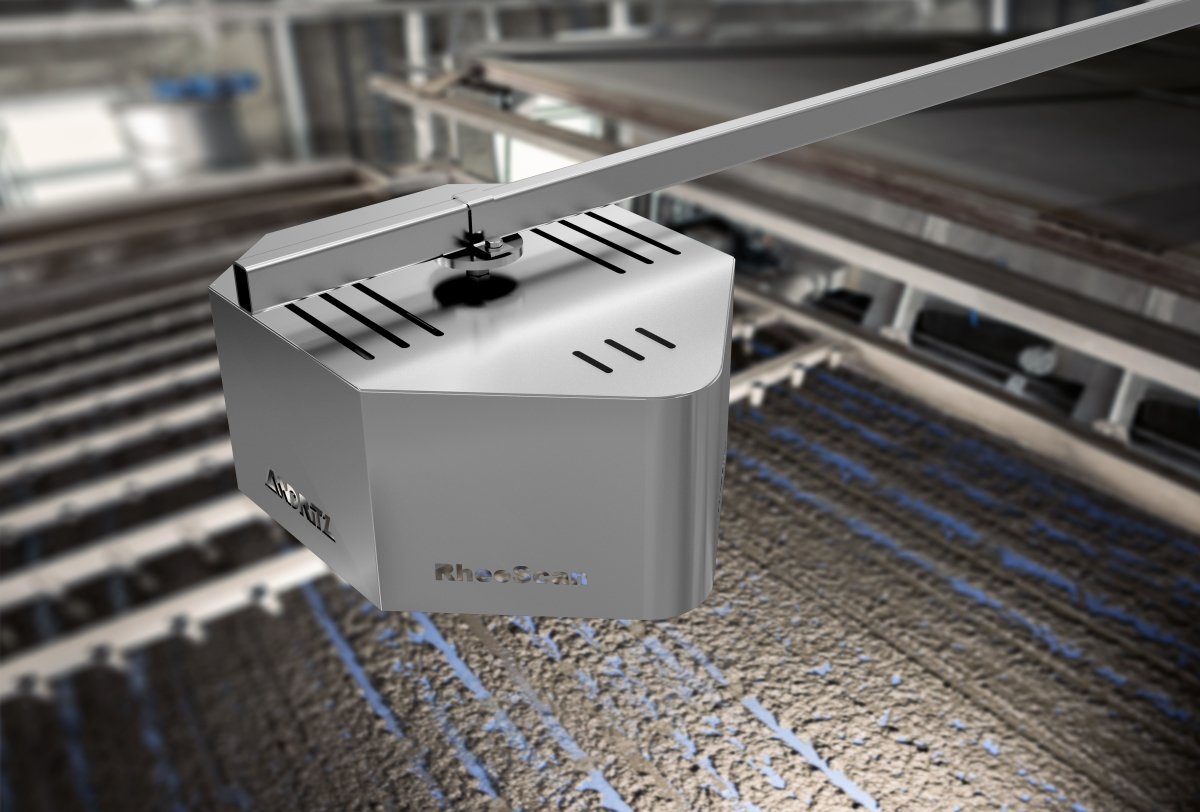

11.11.2021International technology Group ANDRITZ has introduced the next generation of its unique Metris addIQ RheoScan, the world’s first patented, optical measurement system for automatic polymer dosage in belt presses and gravity belt tables.

Metris addIQ RheoScan, patented, optical measurement system for automatic polymer dosage

Metris addIQ RheoScan, patented, optical measurement system for automatic polymer dosage

© ANDRITZ

Among other features, the system now uses artificial intelligence (AI) to further increase process stability and reduce operating costs. Metris addIQ RheoScan measures the actual sludge conditions throughout the thickening and dewatering stages in real time using a convolutional neural network for texture detection. The system adjusts the polymer dose as needed to match changing flow rates and sludge conditions – automatically and with the utmost precision. This allows for almost fully autonomous machinery operation. The new squeeze-control option enables the system to operate at the capacity limits of the machine 24/7, effectively eliminating downtime.

Optimized dosage saves polymer, resulting in OPEX reduction by up to 40 % for sewage sludge, coal sludge or paper sludge dewatering. The cutting-edge technologies used also help to maintain optimum cake dryness and to identify blinded belts which in turn leads to smoother operations. Installations in wastewater treatment plants with digestion processes have seen the additional benefit of higher gas yields. Metris addIQ RheoScan operates without supervision and can be applied to any belt press or gravity belt table in all types of municipal and industrial sludge processing facilities. Customers who have installed a Metris addIQ RheoScan generally recouped their investment in less than a year.