adphos Workshop presented aNIR®/aLITE® Technologies for a sustainable future in drying

30.01.2025adphos, one of the global leaders in advanced digital drying solutions, successfully hosted an engaging in-house workshop, "Transformation from Gas Dryers to Digital Drying – aNIR®/aLITE® Game Changing Technologies," in November 2024 at its premises in Bruckmuehl/Germany.

© adphos

© adphos

The workshop highlighted ground-breaking advancements in thermal drying, offering industry professionals an in-depth understanding of adphos’ digital aNIR® and aLITE® technologies. Through expert-led lectures, live demonstrations, and interactive sessions, attendees gained valuable insights into how adphos solutions are driving efficiency and sustainability in modern production lines.

Exploring the power of aNIR®/aLITE® technologies

Participants were introduced to the advanced capabilities of aNIR®/aLITE® drying systems, which offer a superior alternative to traditional gas dryers. Presentations delved into the advantages of these innovative technologies, including:

- Replacement of traditional gas dryers: High-efficiency, electro-thermal systems designed to replace conventional gas dryers.

- Cost savings and speed: Significant reductions in operational costs and faster processing times.

- Sustainability: A dramatic reduction in carbon footprint, supporting environmentally friendly manufacturing practices.

The workshop also showcased real-world applications and installations where gas dryers have already been replaced by aNIR®/aLITE® systems, underscoring their transformative potential.

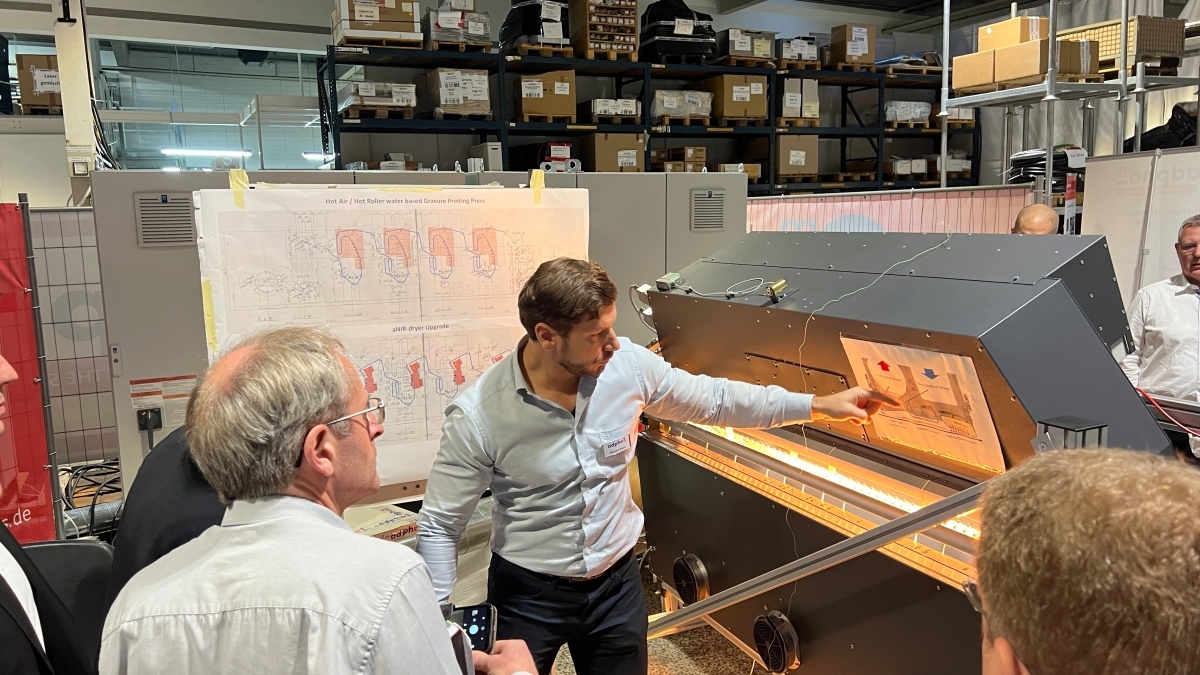

Hands-on demonstrations and facility tour

A standout feature of the workshop was the exclusive tour of adphos’ company premises. Attendees inspected a ready-to-ship production system, gaining first-hand insights into the advanced design, flexible configurations, and scalability of adphos’ solutions.

Live demonstrations brought the capabilities of aNIR® and aLITE® to life, showcasing their unmatched drying precision and versatility across a wide range of industrial processes.

Networking and community building

To complement the technical program, attendees enjoyed an evening social event at a local brewery. This informal gathering provided an excellent opportunity to:

- Network with peers

- Exchange ideas with industry experts

- Strengthen professional relationships in a relaxed and enjoyable setting

Driving the future of thermal drying

The event reinforced adphos’ position as an industry pioneer, demonstrating how its technologies empower manufacturers to transition from traditional gas-based systems to more efficient, digitally integrated solutions.