Wolfram invests in a new Sandvik processing plant in Mittersill

Tungsten features very special properties, which make it indispensable for the modern high-tech industry. Tungsten has the highest melting point of all metals and is therefore ideal for high-temperature applications in energy and lighting technology as well as the aerospace industry. Furthermore, tungsten’s very high density, which is comparable to gold, means that it is used for flywheel weights, counterweights or vibration dampers in aviation, automotive, sports and telecommunications technology. In addition, it serves as a replacement for lead and shields against radiation in medical technology. When bonded with carbon to form tungsten carbide, it has diamond-like hardness and forms the basis of modern cutting and drilling tools for metal, stone, wood and plastics processing. The spectrum ranges from ultra-fine drill bits for printed circuit boards to tools for drilling road and railway tunnels.

Wolfram is a strategically important part of the global Sandvik Group and the only integrated tungsten smelting plant outside of Asia and Russia. As a result, the company has expertise in all aspects of the process, from exploration through to the finished product. Scheelite is extracted in the state-of-the-art underground mine in Mittersill and is used as a primary raw material at the smelting plant in St. Martin im Sulmtal/Austria, together with tungsten concentrates purchased from around the world.

The recycling of secondary raw materials containing tungsten at the recycling centers in Chiplun/India and St. Martin plays an important role in conserving natural resources and completely closing the supply chain loop. For example, used indexable inserts or drill bits are processed back into tungsten powder. The target for 2030 is a recycling rate of 80 %. In the interests of sustainability, investments are continuously made at each site in the optimization of the recycling process, the further development of the circular supply chain and the complete conversion to sustainable energies.

Mining and processing in Mittersill are where Wolfram’s production line begins. Here, 65 employees are involved in mining and another 25 employees in processing. The raw ore is transported into the processing plant in an environmentally friendly manner by means of a conveyor belt through a tunnel. The raw ore is used to produce the scheelite concentrate, which covers a significant portion of Wolfram’s raw material requirements, thus ensuring independence and security of supply.

The deposit’s varying ore grades are defined by means of exploratory drilling. A wide variety of mining methods are used for the selective extraction of the scheelite. The resulting cavities are completely refilled. The drilling work is carried out with face drill rigs, bouldering rigs and longhole drill rigs (down-the-hole hammer and top hammer).

The mining points are connected by a winding main ramp, the lowest part of which is 550 m above sea level. This is 800 m below the main opening and already well below the existing old crushing and processing plant. As the uphill transport route to the crushing plant continues to grow longer as the mining progresses, the construction of a completely new processing plant in the current mining area was discussed for the first time in 2020. After comparing various operating and production factors, which also included the use of electric dump trucks, it was decided that a new processing plant should be constructed around 300 m below the existing plant. An intensive planning phase followed in 2021, during which the Plant Manager Stefan Eggenreich and his team worked together with Project Manager Alois Raffelsberger from Sandvik SRP to develop a solution. After completion of the planning, the contract for the entire machinery and steel construction was awarded to Sandvik Rock Processing CEU in 2021. Before the first assembly work could be started, the cavern for the new processing plant had to be excavated. In close coordination with all parties involved and the responsible authorities, 3D planning of the cavern was precisely carried out with the aid of state-of-the-art measurement technology.

At the end of 2022, the first steel components and machines were delivered, which were gradually moved into the underground cavern. Assembly of the steel structure was started by the company Trost in Matrei in Osttirol/Austria. The innovative, medium-sized steel and mechanical engineering company specializes in large-scale projects in all application areas and its project management team made a valuable contribution to the project during the construction phase of the plant. In the next step, all the processing units, such as the crushing and screening technology, belt conveyors, reciprocating feeders and dosing troughs, were assembled and installed by Sandvik technicians. The assembly work was completed at the end of 2023. Cold and hot commissioning took place in 2024, and the system has been operational since March 22, 2024.

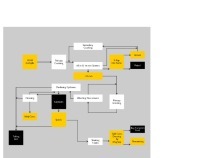

One focal point in the design phase was the construction of the heavy-duty preliminary stockpile with the hydraulically lockable needle gate specially developed for this job, through which blast rubble up to 1200 mm in size is transported away via the lintel shaft.

Both at the needle gate and before the jaw crusher, a Sandvik 999E rammer hammer was installed in order to quickly and safely eliminate potential jams. Below the preliminary stockpile is a Sandvik SH2071M reciprocating plate feeder, which transports the material by means of a hydraulic moving-floor conveyance system via a SV2131 vibrating feeder to an in-line CJ815 jaw crusher. The single-toggle jaw crusher has an inlet of 1500 x 1100 mm and reduces the maximum grain size to 250 mm. Below the jaw crusher is a silo, which has been blasted out inside the mountain and from which the material is transported to a linear vibrating screen via a Sandvik SP1630 pan feeder. Here, the material is separated at 60 mm. Material of 0 – 60 mm in size is deposited in an ore stockpile. Two dosing troughs below the ore stockpile and Sandvik belt conveyors transport the material to a steep conveyor system from which the material is conveyed to the surface installation. Material larger than 60 mm is fed in a closed circuit to a CS840i cone crusher, a premium cone crusher from the Sandvik 800i series. A stockpile is used upstream of this as a buffer to achieve the desired uniformity. Secondary crushing in the CS840i produces a grain size of 0 – 60 mm. The material is screened again via the return belt until the desired degree of particle reduction is reached. The process and layout design, as well as the detailed engineering of the plant, was carried out by the Sandvik Rock Processing team in close cooperation with the client.

Although the construction of the new processing plant represents a major investment, it is much more economical compared to the future operating costs of an unchanged transport concept. Wolfram Bergbau und Hütten AG is thus taking an important step toward future-proof optimization of further mining operations.