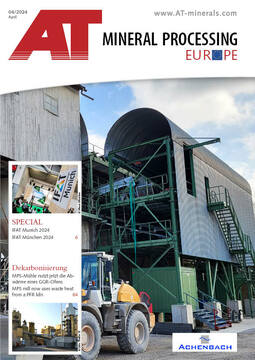

Sandvik hybrid scalping screen for recycling operation

1 Stuart Partners Ltd. have recently invested in a Sandvik QE342e hybrid scalper for their recycling operation

1 Stuart Partners Ltd. have recently invested in a Sandvik QE342e hybrid scalper for their recycling operation

© Sandvik

Originating back to the 1940s, Stuarts Partners Ltd. is a family run company located in Devon. It has evolved over the years from a cattle haulage business into various industry sectors, such as farming, truck sales and servicing, landfill, recycling, skip waste, as well as renewable energy.

Based at the original Hill Barton Business Park in Exeter, the inert waste recycling sector of the business grew in the 1990s, when they started to clean aggregate to make crushed concrete. This is when they first purchased a screener. The process has developed over the years to today where the wash plant is required to operate all year round. Most of the material brought onto their site is now recycled, including the processing and sorting of over 80 000 t/a of inert waste. Upwards of 70 000 t/a is re-usable and sold as quality recycled aggregates.

Needing to upgrade their existing plant, Stuart Partners were in contact with Retec Equipment Ltd, UK & Ireland distributor for Sandvik mobile crushers and screens, to discuss their requirements. A QE342 e hybrid model seemed the ideal fit for their recycling operation. The QE342e is one of the most versatile and reliable heavy-duty mid-size scalpers available on the market today. The ‘e’ hybrid variant offers a plug-in option to operate either in electric or diesel mode to suit the customer’s preferred energy choice. Purpose designed for durability, its crusher-style chassis incorporates a wear resistant rigid hopper and is compatible for 2-way or 3-way split configurations, as well as having the ability to interchange side conveyors.

2 The ‘e’ hybrid variant of the machine offers a plug-in option to operate either in electric or diesel mode

2 The ‘e’ hybrid variant of the machine offers a plug-in option to operate either in electric or diesel mode

© Sandvik

Its heavy duty 4.7 x 1.45 m screen with high speed and aggressive throw is built for tough applications and can handle high volumes of infeed material. It offers user-friendly features for ease of operation, including an electrical control system which improves both operational effectiveness and machine safety, as well as two-speed tracking for faster mobility on site. The unit also comes fitted with My Fleet telematics as standard to optimize the machine performance and maximize productivity.

A quality and reliable brand

Tom Stuart, Site Manager at Stuart Partners’ recycling site said: “We have a long history with Sandvik extending back beyond the ‘Extec days’. We know the brand produces quality, reliable machines, which are exceptionally functional and hold an excellent re-sale value. This time we opted for a dual-power machine to suit our future requirements.”

Stuarts have been granted planning permission to build a new gasification plant which will produce renewable energy on site. This will incinerate waste for electricity rather than sending it to landfill, reducing greenhouse gas emissions and recovering valuable energy. To be able to produce their first energy from waste plant, running on a neighbouring site, will mean that they will be able to power the wash plant and then also the Sandvik QE342e using renewable energy. “So the reliability, flexibility, range of options and re-sale made the QE342e the best choice,” Tom Stuarts comments, when speaking of why they chose Sandvik.

He says they are currently operating the QE342e through an external generator and using it to separate larger fractions of material, which would be too large to go through their wash plant (60 mm plus), from the smaller fraction (0 to 60 mm). It is used as the main feed and regulates the speed of throughput of the wash plant. The smaller fraction is fed into the wash plant. The larger material is then processed through a crusher and sold as a crushed concrete, or 6F5. Once the screened material is processed through the wash plant, the aggregates are used by a wide range of customers, such as utilities, commercial builders and even farmers for the sand. The larger material that is crushed is mostly used by commercial builders.

Lower operating cost, higher uptime

In addition to the sustainability of the hybrid drive, the QE342e offers many additional benefits in terms of lower cost of ownership and higher uptime. With less moving parts and filters, less time is required for maintenance meaning the machine can be operational for longer. The unit is fitted with the latest generation, efficient Stage V engine for maximum performance, reduced fuel consumption and lower environmental impact. The hydraulic system is optimized and reduced engine RPM lowers fuel consumption, whilst a well-proportioned fuel tank maximizes intervals between refueling. There is also a 50 % hydraulic fluid saving with extended service intervals from 2000 to 4000 hours.

All mobile units also leave the factory in Northern Ireland with HVO renewable fuel in the tank, contributing to cleaner operation and a lower CO2 footprint.

“We have been really pleased with the machine so far. We have noticed a big step forward from our previous model (2008) in terms of electronics managing the RPM of the engine. The plug-in electric will be a big step forward when we have the infrastructure in place,” comments Tom Stuart. “The ease of removing the mid-size conveyor and the ability to reconfigure to our requirements has also been a real positive.”