Reversible SMR impact crushers from SBM

Especially in times of constantly rising basic costs such as energy or personnel expenses, the highest possible added value in operation is becoming increasingly important. For extraction and processing operations or recycling companies, what counts here is not only cost-effective production processes, but also optimal utilisation of the extracted rock to produce the largest possible proportion of well-marketable end products. The focus here is on certified quality aggregates for road construction, high-quality mineral and aggregate materials for asphalt and concrete, and certified recycling materials. The value of supposedly inferior aggregate mixtures from quarrying and production is also being put to the test. What used to be an oversize material that hardly yielded any income and was not infrequently backfilled can today, in view of a decreasing overall supply or new recycling channels, certainly contribute to the company’s results.

Today, many companies are making correspondingly great efforts in the necessary quality-oriented conversion and upgrading of the secondary and tertiary stages of their processing lines. In addition to the product properties, such as particle shape or fracture surface, a large proportion of valuable grains and a high consistency of the delivered grains are decisive for the economic efficiency of the investment.

Alternative to pressure crushing

In single- or two-stage sand and grit refinement, cone or gyratory crushers are still primarily used – often with a downstream vertical impact crusher to achieve the necessary cubicity, depending on the rock requirements. Up to now, the partially high wear of conventional impact crushers in the crushing of abrasive types of rock or materials has been an argument in favour of this large mechanical effort with correspondingly high energy and maintenance costs.

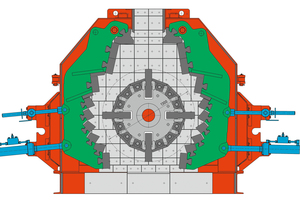

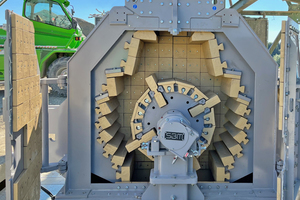

With its reversible impact crushers SMR, SBM Mineral Processing has been offering a wear-optimised crushing technology for several years, which nevertheless combines all the advantages of impact crushing such as good grain shape, a well-controllable fines content or high performance with universal applicability. The SMR series now comprises five models with throughput capacities from 100 to 300 t/h, whereby all crushers are characterised by compact dimensions and vertical feeding for feed sizes from 150 to 250 mm. This predestines them for direct use as secondary crushers (e.g. directly behind the jaw crusher), which often enables the saving of a machine/crushing station, additional conveying equipment and the corresponding energy costs when converting or retrofitting stationary plants. Integration into existing lines is facilitated by the electric drive and the simple control/monitoring of the crushing process via frequency converter.

Universally applicable

SMR crushers are suitable for the selective crushing of soft to hard materials such as natural stone, gravel or slag and can also be used for gentle but efficient asphalt recycling (< 1 % bitumen adhesion to the individual fractions) or in the production of mineral fertilisers. In the production of mineral raw materials, they are convincing due to their high medium grain content in the sand or grit range with a low filler content. The crushed product is very uniform even with inhomogeneous raw materials or discontinuous utilisation and has up to 90 % conformity in cubicity with a constant grading curve. This means that the SMR technology as a semi-mobile unit can also be used highly profitably in the temporary processing of previously underutilised oversize or other rock stockpiles.

In addition to the crushing gap adjustment, the crushing process is mainly controlled by the simple adjustment/fine tuning of the rotor speed (25 – 50 m/s). This enables the production of high-quality high-grade chippings (SI < 10%) from hard rock as well as the rational production of asphalt granulations with standard-compliant fracture surface, for example from gravel 16/150 mm. The reversible direction of rotation ensures continuously sharp edges of the four blow bars (optional 2), thus guaranteeing consistent quality and also enabling uncomplicated product changes during operation (e.g. concrete chippings 0/22 to grain mixture 0/45).

Low wear for optimum availability

The change of direction of rotation also favours the high degree of utilisation (> 50 %) of the blow bars and thus long service lives of the easy-to-change tools. At the same time, all SMR models impress with good accessibility for maintenance purposes: via wide-opening doors on both sides, the impact plates, which are only pushed in, can be easily replaced or the wear plates of the side armouring can be changed quickly. There is no comparison to the time-consuming maintenance and repair of cone or gyratory crushers, not even when lubricating or regularly checking the electric belt drive with spherical roller bearings: only six lubrication points need to be supplied once a week, and if necessary all parts on the drive can be obtained from independent dealers and replaced by the operator’s own personnel.

Extensive experience

Since the end of the nineties, SBM and its trading partners have sold a total of 375 SMR machines internationally and for a wide variety of applications. Today, the long-term experience in the various industries is correspondingly large – especially with regard to the potential savings that can be made by switching to reversible impact mills.

In addition to comparative values, SBM also offers short-term tests using semi-mobile units – in the case of large-scale plant conversions or new construction, in-depth process analyses in SBM’s own rock laboratory form the basis for meaningful performance forecasts of the new crushing stages.