ProSpare Ltd

ProSpare Ltd will be using Hillhead 2024 as the platform for the UK launch of the STARCLEAN® S³. The innovative conveyor belt cleaner and monitoring system enables continuous, contact-based control of the conveyor belt and scrapers. It contributes greatly to a lower maintenance, more efficient, and safer conveyor system.

© ProSpare Ltd

© ProSpare Ltd

STARCLEAN® S³ allows for predictive maintenance of the belt cleaners and protects the belt itself through preventive damage detection. This digital innovation gives the scraper the ability to self-regulate wear and tear whilst also ensuring a constant pre-tensioning force – completely automatically.

An innovative conveyor belt monitoring system with belt damage detection

STARCLEAN® S³ is the new intelligent scraper that combines a proven electric drive with a number of smart modules to detect conveyor belt damage early and allow preventive repair. This saves time and money, reduces maintenance and safeguards conveyor performance.

The S³ operates through advanced, touch-based scanning technology. This analyses the movement and surface structure of the belt to detect possible damage and allows reaction before the production process is seriously impaired.

Damage such as punctures, cuts, repair damage, belt slits, cover plate damage and connection damage can be detected. Following detection, the belt cleaners can be autonomously engaged and disengaged using the electric linear drive. Advantages include:

- Continuous monitoring of the belt

- Prevention of unplanned conveyor downtime

- Improved operating reliability

- Damage limitation

- Efficient use of resources

- Transparent data assessment

STARCLEAN® S³ Modules and Cloud Dashboard

STARCLEAN® S³ is constructed through the combination of a number of interconnecting modules, including STARCLEAN® belt cleaners; Scraper Intelligence Module (SIM); Motorisation set with S³ sensor system; and Measuring roller with sensor system.

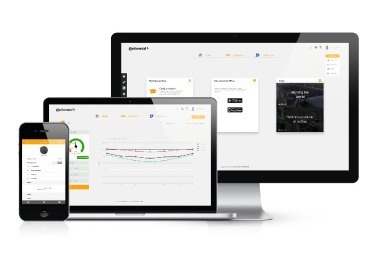

The newly developed STARCLEAN® Cloud is a user-friendly dashboard where all the assembled data appears, such as km per operating hour, condition of the belt cleaners, and a wear display. In addition to monitoring, the Cloud provides intervention in the system components.

The Scraper Intelligence Module (SIM) is the heart of the STARCLEAN® Smart Scraper. It automatically controls the components and passes the captured data to the Cloud, which allows monitoring of the whole process.

The S³ sensor system recognises belt properties and detects damage events via feedback from the belt cleaners. It is possible at any time to see an update of the belt profile, observe the damage/profile, and individually set the damage level.

The measuring roller detects conveyor direction, position, belt length and speed. This also ensures precise localisation of the damage. Detection of movement direction is especially important with reversible belts, because the scrapers can be engaged and disengaged automatically using the motorisation set.

All data is visible in the STARCLEAN® Cloud, allowing users to monitor the system and take action as soon as an issue occurs. Depending on the damage level, STARCLEAN® S³ can take action independently or even initiate an emergency stop of the belt system if desired.

STARCLEAN® Cloud features include:

- Continuous conveyor belt monitoring

- Detect the position of belt damage, classify belt damage, and define internal damage level

- Initiate action if belt is damaged (disengage scraper, send messages, signal alarm)

- Graphic representation of belt properties

- Detail condition of conveyor belt (operating hours, mileage, etc.)

The STARCLEAN® S³ joins the wider STARCLEAN® belt cleaner range offered by ProSpare in UK. ProSpare are a trusted partner to improve belt conveyor performance, particularly by addressing cleaning, tracking, and sealing issues. We help materials handling businesses in a wide range of industries including quarrying, cement, construction, and recycling, and have supplied over 2500 STARCLEAN® scrapers throughout the UK.

Stand: F6