Powerful innocrush ic35 impact crusher copes with increased recycling volumes of the future

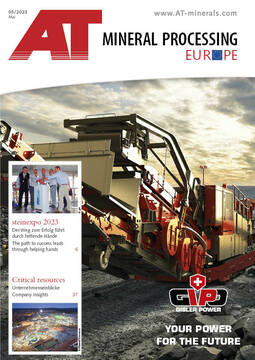

1 The innocrush ic35 high-performance impact crusher is used e.g. for construction waste recycling

1 The innocrush ic35 high-performance impact crusher is used e.g. for construction waste recycling © innocrush

The customer comments: “In order to cope with the additional recycling volume, we decided on the high-performance innocrush ic35 crusher with a 1280 rotor. We already had a plant and were very satisfied with both the product and the company’s service. Therefore, the decision-making process was much easier for us than before. We were able to visit various crushing plants from well-known manufacturers, but the performance of the ic35 and the overall package convinced us during the innocrush plant demonstration. Basically, the performance of the plant is important for us and this is where the plant shows its strengths. It is also easy to maintain due to the hydraulically opening engine compartment and the good accessibility of all components. In addition, the spare parts supply from innocrush is quick and unbureaucratic. Once, on a time-critical construction site, we had to replace wear plates at the weekend, which we unfortunately did not have in stock. We contacted innocrush and were able to pick up these plates on Sunday and replace them at our ic35 crusher. By Monday we were able to get back to work.”

In addition to processing concrete, construction waste and asphalt, the high-performance crushing plant can of course also be used for gravel processing. Due to its compactness and relatively low weight, flexibility makes it easy to handle even small recycling jobs. The company also operates as a contract service provider, where fast and clean processing on site is crucial in order to be able to reuse the material on the spot. Incidentally, there is no need for targeted advertising, “word-of-mouth” is quite sufficient, according to the construction company. The problem-free transport with a dead weight of 32.1 tonnes (depending on the equipment) naturally facilitates the versatile application possibilities. The chain drive of the plant has been revised to ensure even more effective movement of the plant. Mobility and flexibility are the key features here.

The performance data are also convincing: the innocrush bucket has an infeed width of 1250 mm and a remarkable throughput capacity of up to 380 t/h. In addition, there is, among other things, a hopper extension, a performance measuring device and much more. The impact crusher is equipped with a separately hydraulically adjustable primary and secondary crushing stage in combination with an optimal crusher geometry. The rotor speed can be infinitely varied to influence the quality of the end product. As an option for the future, the ic35 is already prepared to accommodate a screening plant with a return belt. This can then be picked up independently by the crushing plant.