Our employees are the key to success

One of the key assets contributing to the success story of AKW Equipment + Process Design has always been and still is its experienced team and loyal employees. Their know-how, expertise, culture of collaboration, and forward-thinking are key components to the company’s accomplishments and ensure that AKW Equipment + Process Design is always at the cutting edge and one step ahead of its competitors. In the interview Thibaut Richard, General Manager at AKW Equipment + Process Design, looks back on 60 years of success in the world of highly customized wet mechanical treatment solutions.

What stands behind 60 years of AKW Equipment + Process Design?

Thibaut Richard: Already more than 100 years ago, kaolin, feldspar, and silica sand were produced in Hirschau, which is located in the north of Bavaria/Germany, where AKW Equipment + Process Design was founded in April 1963 to support the local industrial mineral resource producers in multiple ways: improve current production performances, invent new processes for new products and applications, debottleneck existing process steps, and so much more. Up until today, our Headquarters and major engineering resources are still located within this area. Such loyalty to a local environment would not have been possible without the strong, long-lasting involvement and support of the company’s owners and principal shareholders – the brothers Thomas and Johannes Heckmann – who are originally from Hirschau and still live in the region. Step by step, the success and reputation of the company also naturally led to the supply of international projects across the world. This made the company what it is today: one of the leading specialists for high-quality equipment and plants for the wet mechanical processing and valorizing of mineral resources.

Compared to the beginnings, where do you see the company now?

Thibaut Richard: Well, since our founding and as per the nature of our business, we have been taking a proactive approach to the issue of globalization and the opportunities it represented. As a result, nowadays the company can benefit from the set-up of a very successful JV in China (with us holding a majority stake) which celebrated its 15 years anniversary in 2021. As environmental-related technologies and process solutions have become increasingly important for the Chinese market, we founded a new company, called VORTEX, in 2020 that would exclusively focus on and deal with these matters. Furthermore, we benefit from two important sales and service offices for the Russian-CIS and Middle East, as well as a pool of professionals and competent agents in those regions. The sales mix evolution – nowadays with a minimum of 50 % of our yearly revenues generated outside of the EU – has shaped our corporate culture, capabilities, and resources, accordingly, positioning us today as a well-established, globally reputed, successful EPC player with loyal customers and hundreds of executed plants worldwide.

Over time it became clear that our technical center equipped with both physical and analytical capabilities spread over a 900 m2 area and staffed with 6 people is inevitable and beneficial for our daily business. Although it is difficult to generate impactful innovations in the sector of wet mechanical processing, breakthroughs can still be found and in essence, working on mineral processing with a fully equipped technical center, where both lab-scale and pilot-scale test works can be organized, gives us unique insights to improve our existing knowledge as well as staying close to the market’s concerns. This allows us to evolve requirements and find the best solutions for our client’s problems. I must stress the fact that AKW Equipment + Process Design is still one of the few companies benefiting from such an internal asset, that enables us to turn around a complete wet mechanical treatment solution from the concept to realization. On a yearly basis, we practice more than 300 test works in our technical center, with material samples coming from all geographical areas.

Being in the business for 60 years there must have been several important and groundbreaking milestones for AKW Equipment + Process Design. Can you please share some of such key moments?

Thibaut Richard: If we focus on company milestones per se, we should start in 1986 when we became fully independent from any industrial group as this was an important event for our company. In 2005 we then constructed and relocated to our main office premises where we also built our new state-of-the-art technical center and laboratory in 2011, bringing us to another level of expertise and positioning in the market.

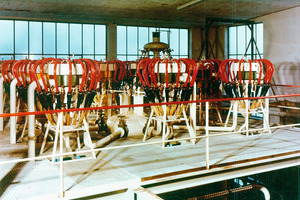

In terms of markets and project successes, there have been multiple milestones reached and reasons to celebrate. Firstly, we became one of the major references worldwide in hydrocycloning solution design. Furthermore, we developed some unique expertise in the fields of clay and silica sand treatment, introduced new classification solutions in alumina processing, were the first ones to recycle blast furnace sludges, and got granted a European award. We also developed and implemented the first soil-washing recycling plant in the leading Swiss market and supported the coal-fired power plant to improve its environmental footprint through the so-called flue-gas-desulfurizing process. Last but not least, we should not forget about the fact that we erected the first plastic recycling installation for pre-separated plastics from household waste back in the 1980s in Germany.

Some of the process solutions designed by our company over time still constitute nowadays the best-in-class and clear benchmark reference point. This shows how strong our know-how, reliability, and success have been. More recently, we started being exposed to the digitalization megatrend. Although this new feature is definitely bringing advantages for some of our process solutions, for example, in 2023 we are in the process of releasing a new and revolutionary software approach for our AKOREL system, I also believe that we must remain cautious not to simply obey to a trend that likes to push you to increase the digitalization level on all your equipment and solutions too quickly, especially when the results behind are not proven. Digitalization at AKW Equipment + Process Design will never dictate the customer experience, but rather improve it in a meaningful way.

What is your outlook on the future?

Thibaut Richard: Many companies strive to keep growing and growing, always looking for more. At AKW Equipment + Process Design, we recognize the need to remain a profitable company to keep capabilities for investing in new resources, ideas, partnerships, and manufacturing capabilities. However, the focus on growth should not be done at the expense of our service and customer focus. In a similar way, we have always been positioning ourselves as a company offering customized and tailor-made solutions, and we do not aim to move away from this motto.

The way our solutions and technologies can impact the environment is also becoming of growing concern, and already require our engineers to think differently about some of our proposals and integrate new recycling and optimizing loops. These are both new challenges as well as outstanding opportunities, to anchor the company in the next chapter of its development. The frugal approach which we have for growth and profit generation, supported by the shareholders, is surely the way to go and move forward for sustainable growth and success. We are proud of what we have achieved over the past 60 years and are excited about what’s next – a future full of innovations, success, collaborations, and great teamwork.