Optimized filter belts for dewatering processes

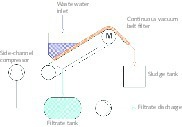

Whether for phosphogypsum or salt dewatering in fertilizer production, FGD gypsum dewatering in power plants or the dewatering of mining residues: Filtration efficiency, productivity and process reliability are crucial for success in global competition. The VACUBELT® filter belts from GKD, which have been specially developed for continuous vacuum belt filter systems, make a significant contribution to this. This is because continuous belt filter processes place high demands on the system components. The performance and service life of the filter belts used are decisive for the efficiency and productivity of the systems.

Dewatering of mining residues

The mining industry is constantly faced with the challenge of disposing of tailings in a safe and environmentally friendly manner. One of the most effective methods for accomplishing this task is dewatering by means of vacuum filtration, especially with vacuum belt filters. Dewatering significantly reduces the volume of the tailings. This makes the residues more compact and allows them to be stored more safely. Large tailings dams and the associated risks to the environment can be effectively reduced.

From the point of view of sustainability, there is another aspect to be mentioned: In water-scarce regions of the world, the recovery of process water is of great importance. The use of VACUBELT® filter belts in vacuum belt filter systems makes a significant contribution to efficient water management, which not only offers ecological benefits but can also significantly reduce operating costs. Long service life, high dewatering performance, fast cake build-up and good cake discharge are just some of the advantages of VACUBELT® filter belts.

Efficient dewatering of phosphogypsum

Phosphorus is essential for plants, teeth, bones and the immune system of humans and animals. In 2022/2023, around 116 000 tons of phosphate fertilizer were used in German agriculture alone. Phosphogypsum is a by-product of fertilizer production. This by-product must be efficiently dewatered before final disposal, for which VACUBELT® filter belts from GKD are ideally suited. These filter belts are characterized by high lateral stability and controllability, are robust against mechanical, thermal and chemical loads and ensure maximum dewatering efficiency thanks to high air permeability and low clogging tendency.

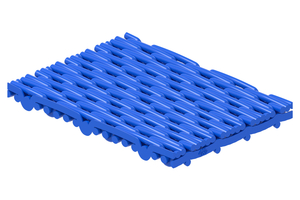

VACUBELT® filter belts are characterized by their special design, which makes them ideal for large system dimensions. The smooth fabric surface enables optimum cake discharge and easy cleaning. The flat PAD seam of the VACUBELT® filter belts reduces particle penetration and significantly extends the service life compared to conventional staple seams.

Salt dewatering in potash fertilizer production

High temperatures and corrosive conditions prevail in potash fertilizer production. VACUBELT® 5060 filter belts are characterized by their single-layer design and mesh widths of up to 490 μm, which enable high dewatering performance. Their robustness and lateral strength guarantee a long service life and reliable tracking. The special PAD seam ensures a closed and durable seam zone, thereby increasing productivity and efficiency.

Optimized FGD gypsum dewatering

The world’s largest coal-fired power plants rely on VACUBELT® 2015 filter belts for FGD gypsum dewatering. These are made of pure polyester monofilaments and offer high air permeability, fast dewatering and low clogging tendency thanks to their specific fabric construction. Their thermal resistance and excellent cleaning properties make them the ideal choice for the demanding conditions in FGD gypsum dewatering.