MPS mill now uses waste heat from a PFR kiln,

saving 600 t of CO₂ annually

In the interest of environmental protection, operating cost considerations, and natural gas savings in times of natural gas scarcity, a grinding plant at the Merdingen plant of Hans G. Hauri KG Mineralstoffe was converted in two steps to enable waste heat recovery. The work was conducted in cooperation with the manufacturer of the kiln, Maerz Ofenbau AG, and of the grinding plant, Gebr. Pfeiffer SE.

Introduction

Hans G. Hauri KG, a family business based in the German state of Baden-Württemberg, specializes in quarrying and refining volcanic rock from the Kaiserstuhl region and limestone from local quarries (Fig. 1). Since 2017, Hauri has also been producing highly reactive quicklime at the Merdingen site using a newly constructed PFR kiln from Maerz Ofenbau AG (Fig. 2).

In the interest of environmental protection, operating cost considerations, and natural gas savings in times of natural gas scarcity, a grinding plant at the Merdingen plant of Hans G. Hauri KG Mineralstoffe was converted in two steps to enable waste heat recovery.

In addition to the obvious natural gas savings, the first step also served to enable use of the smallest possible burner so that after the second step, it would be possible to reduce the demand for natural gas to the smallest possible quantities.

Utilization of the waste heat alone makes savings possible of approx. 3.5 million kWh of natural gas, or expressed differently, approx. 600 t of CO2 annually.

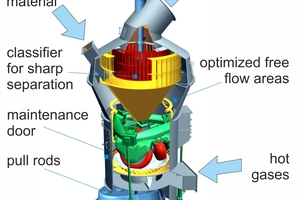

Step 1: Additional air recirculation to the hot gas generator of the grinding plant

The existing grinding plant built in 1989 by Gebr. Pfeiffer contains a vertical roller mill of the type MPS 140 A (Fig. 3) from Gebr. Pfeiffer as the main component, and a hot gas generator (HGG) of the type HML/G 900, also from Gebr. Pfeiffer. The HGG was retrofitted in Step 1 to make it capable of air recirculation. The dilution air is now no longer fed using fresh air, but process exhaust gases instead.

The less ambient air has to be heated to the chimney outlet temperature, the less “unnecessary” heating requirement there is. Gebr. Pfeiffer had predicted natural gas savings of 5 to 8 %.

Hauri implemented the additional, insulated, recirculated air piping according to the specifications provided by Gebr. Pfeiffer.

This opportunity was also utilized to install a more powerful dilution air fan with a frequency converter (Fig. 4).

Direct recirculation of a portion of the grinding plant exhaust gases was implemented.

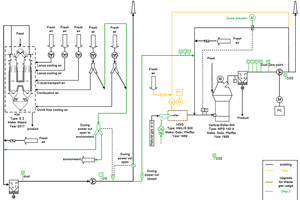

The moderate exhaust gas temperatures and moderate feed moisture content made it possible to omit any conditioning of the air recirculated to the HGG (Fig. 5).

Special challenges involved in Step 1

Due to its design, the HGG provided by Gebr. Pfeiffer also requires the dilution air for cooling purposes of its housing. This made it imperative to ensure that it is supplied with at least the required amount of dilution and cooling air at all times.

The additional recirculation of the process gases meant that the issue of the dew point required special consideration. If the dew point distance becomes too small, the temperature after the classifier must be raised or the feed rate lowered.

The plant needed to be capable of being operated at all times in the same manner as before the modification.

Insights gained on the grinding plant after Step 1

Operation from July 2022 to December 2022 after Step 1: In this short period of time, it was not possible to quantify the savings of natural gas conclusively, as the time period was too short and the dependency on weather and precipitation too great. There was also no complete annual cycle of ambient temperatures. However, the initial figures indicated natural gas savings of about 10 %. The dew point was checked regularly by means of manual measurements at the chimney. No dew was observed at the chimney.

Step 2: Incorporation of the kiln exhaust gases

This step was subsidized by the Federal Office for Economic Affairs and Export Control (BAFA), Module 4.

Maerz Ofenbau AG provided assistance for this subproject right from the start by supplying Hans G. Hauri KG with engineering support, material and personnel for the commissioning. To ensure that the high level of safety present in the existing plant was maintained, Maerz Ofenbau AG performed a risk analysis for functional safety in the first phase. The results of this analysis were then incorporated in the design of the plant’s process and measurement technology as well as the control system.

The major fuel consumers in the plant are the Maerz E2 PFR kiln (Fig. 2), built in 2016, by Maerz Ofenbau AG, and the combined grinding and drying plant from Gebr. Pfeiffer described here with the MPS 140 A and the HML/G 900.

All exhaust gas that exits through the chimney, along with the waste heat it contains, is lost for the plant. If there is a need for further heat, it must be generated once again through combustion.

The exhaust gas of a PFR kiln contains energy and a certain temperature along with a moderate dew point, so that it is in principle conceivable to use it as a hot gas supplier for the grinding plant. This would then reduce or even eliminate the need for hot gas generation at the grinding plant.

However, the design of the PFR kiln means that it cannot supply the exhaust gas at a constant quantity or consistent temperature. Every time there is a switch from one shaft to the other, the kiln pressure must be relieved, resulting in the exhaust gas being abruptly produced at a significantly lower gas volume flow rate and temperature for a short time.

To the knowledge of the team of authors, no attempt has yet been made anywhere in the world to use exhaust gases from a PFR kiln as a heat source for a grinding plant with a vertical roller mill, since vertical roller mills from all manufacturers are sensitive to fluctuations in volume flow.

The exhaust gas quantities produced by the kiln and the grinding plant are in the same order of magnitude, meaning that no parts of the grinding plant that conduct process gas required any changes in size. The plant fans of the kiln and the grinding plant have sufficient reserves so that no booster fan is needed for the long transport path between the two plants.

Insulated exhaust gas ducting was routed across the plant by Hauri according to Gebr. Pfeiffer’s specifications. This serves as a hot gas supplier for the grinding plant.

Since the kiln exhaust gas has a lower dew point than the mill exhaust gas, the dew point issue in the grinding plant became slightly less problematic compared to Step 1. Nevertheless, the minimum required dew point distance is ensured by the process control mentioned above (Fig. 5).

Special challenges involved in Step 2

The exhaust gases from the PFR kiln contain a good deal of CO2 because the kiln produces quicklime. Due to its construction, a grinding plant is not hermetically sealed. To protect personnel from the danger of asphyxiation through CO2, a great deal of attention was given to ensuring that no CO2 can accumulate in the grinding plant building when the kiln is operating but the grinding plant is switched off, and that should this nonetheless occur, it would be noticed immediately. The CO2 sensors from ExTox have proven to be invaluable here. Emergencies, such as a power outage, have also been taken into account. Apart from the chimney, the grinding plant is subject to negative pressure when in operation, so that, even if there were leaks, there is no fear of CO2 escaping.

Both the kiln plant and the grinding plant can now be operated separately as well as in combination. A changeover during operation is also possible.

The old type S5 control systems were unable to take on the additional tasks, so a higher-level type S7 controller is used as well for the coordinated operation.

The exhaust gas temperatures of the PFR kiln were lowered to the greatest extent possible in the past for reasons of energy conservation, and the temperatures and energy content were almost too low for the grinding plant’s requirements. To be able to heat the grinding plant 100 % with the kiln exhaust gas with the kiln at full load required the kiln exhaust gas temperature to be raised slightly from 120 °C to 130 °C. When the kiln is at partial load, additional heat is produced in the grinding plant with the HGG used previously. The burner of the HGG was already being operated at extreme partial load after Step 1 so that a smaller burner could then be implemented as part of Step 2. The objective was to realize the lowest possible natural gas demand at partial load of the kiln

An important requirement was that the hightemperature process of lime burning be operated independently of the waste heat utilization in a self-sufficient and safe manner. If there are any disturbances in the operation of the mill, the SIL controller of the Maerz kiln controls the two dampers in such a way that ensures the kiln exhaust gas is always discharged safely – by removing the option of waste heat utilization if necessary. To accomplish this, safe pressure measurement and, for explosion protection, safe CO measurement were installed downstream of the kiln‘s filter fan.

A pressure sensor was installed to compensate for any pressure fluctuations from the grinding plant and to ensure safe discharge of the PFR kiln exhaust gases. In the event of malfunctions, it ensures that the exhaust gas damper opens and the exhaust gases are discharged with no hindrances. However, in order to have as much hot exhaust gas from the kiln as possible available in the grinding plant, the negative pressure upstream of the mill is controlled in such a way that the kiln exhaust gas damper can remain closed.

Continuous filter monitoring was installed because the long ducting path across the entire plant does not have a sufficient gradient and to ensure that no filter dust, which also contains CaO, can get into the powdered limestone.

The greatest technological challenge, however, was to prepare the grinding plant to deal with fluctuating volume flows from the PFR kiln. In this context, two large plant fans of the PFR kiln, which previously blew into the surrounding area while the shaft is being switched, were reconnected in such a way that during the time of the shaft switch, they also blow into the duct in the direction of the grinding plant after the kiln. In addition, the damper in the recirculated air ducting of the mill was equipped with a fast drive, and this is used to actively control the negative pressure upstream of the mill in order to provide the mill with as constant a volume flow as possible. The hot gas temperature arriving at the grinding plant is kept almost constant over the long ducting path, including a filter housing, due to the heat capacity of the steel. Other technological measures were prepared (e. g. temporary self-learning control of the damper in the recirculated air ducting instead of fixed regulation – to enable optimal processing of weather-related fluctuations in the feed material over the annual cycle – or temporary partial operation of the mill) but these functions were not necessary. The mill operates perfectly with what it now has.

Conversion of the kiln to a variable exhaust gas temperature

for Step 2

The ability to lower the stone level and increase the cooling power of the quicklime provide two means of intervention, allowing the exhaust gas flow temperature to be influenced moderately. These measures are only worthwhile if the waste heat is used frequently.

Insights gained on the kiln modified for Step 2

As of June 2023, energy prices have fallen considerably, thus making many of the premises for the project obsolete. The approach of having to supply as much waste heat as possible to the grinding plant is no longer necessary.

Insights gained on the grinding plant after Step 2

After fundamental considerations on the part of Gebr. Pfeiffer and concomitant specifications for dampers and ducting, Hauri was able to implement the modification on their own. As commissioning was slated to take place between Christmas 2022 and New Year’s Day, Gebr. Pfeiffer described the process for commissioning in detail. Commissioning took place as scheduled in December 2022. At this point in time, the kiln was only in partial operation and a small amount of natural gas was still required for the grinding plant. The mill was operated with a high, but not maximum, tonnage. The commissioning turned out to be unproblematic.

The combined operation has been in effect since 27 December 2022 and is always utilized when both plants are operating at the same time.

Currently, the grinding plant can be operated at about 60 % of the grinding capacity, adapted to the increased waste heat supply of the PFR kiln, without using natural gas.

In terms of process technology, the specific electricity demand has increased due to the partial load operation and the natural gas requirement has dropped to “zero”. Operationally, energy-related grinding costs have been cut in half compared to 2022 – about half of those savings are due to falling energy costs and about half are the result of this project.

Consequently, the combined grinding and drying plant is currently being operated exclusively with waste heat.

If the market demand for powdered limestone increases and the waste heat supply is not sufficient for these quantities, hot gas generation can be added.

Reduction of emissions

The use of dedusted exhaust gas in the form of a series connection leads in practice to a reduction of the dust load of the kiln during the time when waste heat utilization is in effect. In light of this circumstance, the Freiburg Regional Council was able to grant the application according to the German Federal Immission Control Act very quickly.

The linking of a plant subject to emissions trading under European law with a plant not subject to emissions trading involving the use of waste heat also means that the CO2 emissions that are demonstrably saved should be credited. This entails the necessity of measuring the heat flow with as much precision and energy efficiency as possible.

This is not an easy undertaking with the large measuring cross sections involved in flows of hot gas. Moreover, straight inflow sections with access to a sensor position are not easy to find in the existing plant. Differential pressure-based dynamic pressure probes appeared to be a viable solution here. The technology is comparatively inexpensive, can easily be retrofitted, entails only low pressure losses and can withstand high temperatures. Compared to traditional primary elements such as venturis or orifices, both the acquisition costs and the installation costs are low. The condensates due to their large measuring openings – and, what’s more, they are often already present in other plants in the building materials industry. systec Controls can also calculate correction factors for shortened inflow sections. The dynamic pressure probes were manufactured and installed after the inflow conditions were recorded on site. During the commissioning performed by the manufacturer, systec Controls, the correction factors for the shortened inflow sections were taken into account, resulting in deviations of < 1 % in the mass balance between 10 000 and 35 000 Nm³/h. Based on the precisely measured flow and temperatures, the heat output of the individual gas flows can then be determined using the flowcom heat quantity calculator.

Conclusion

It is possible to use recirculated air in hot gas generators from Gebr. Pfeiffer after a retrofit. However, the dew point then requires special attention and is now measured continuously.

The PFR kiln from Maerz Ofenbau AG can be set for different exhaust gas temperatures depending on whether it is operated with or without a grinding system.

Gebr. Pfeiffer mills and grinding plants are able to cope with fluctuating hot gas volume flow rates. However, this requires measures to be taken to achieve uniformity.

Perspective

Gebr. Pfeiffer also offers basic engineering for an advanced system of grinding plant waste heat utilization for customers with (seasonally) higher feed moisture content.

This consists of a combination of direct (process exhaust gases go back into the process, 100 % heat utilization of the recirculated gases, but with moisture accumulation) and indirect (ambient air is preheated by a heat exchanger, efficiency of 50 to 70 % of the excess heat of the total volumetric flow going to the chimney, no moisture accumulation) exhaust gas heat utilization and establishes at any given time at least the necessary minimum dew point distance, thus always enabling the maximum possible waste heat utilization.

If combined waste heat utilization proves to be of interest for the project at hand, it could be implemented here as well.

Authors:

Hanko Spitznas1, Senior Manager Technical Customer Service

Marcus Hauri2, Head of Production

Rainer Zwick2, Technical Manager

Ian Hug3, Head of Global Service

1 Gebr. Pfeiffer SE, Kaiserslautern/Germany

2 Hans G. Hauri KG Mineralstoffwerke, Bötzingen/Germany

3 Maerz Ofenbau AG, Zurich/Switzerland