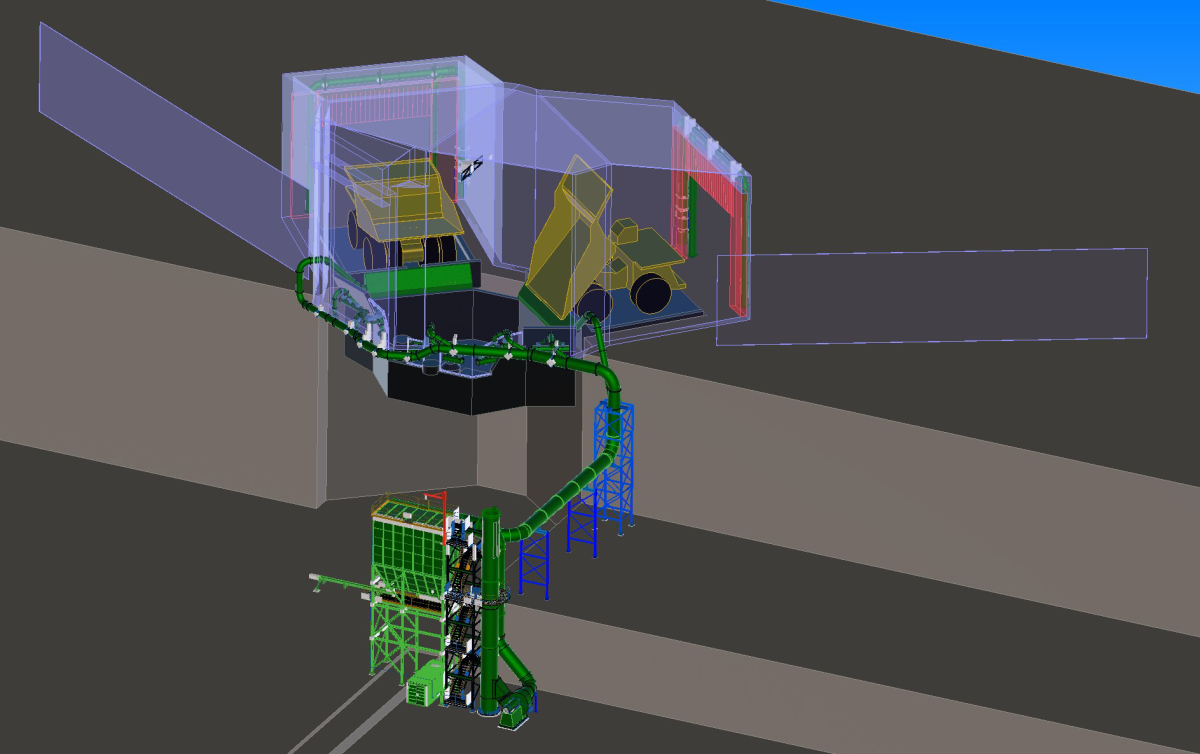

Modernisation for copper mining

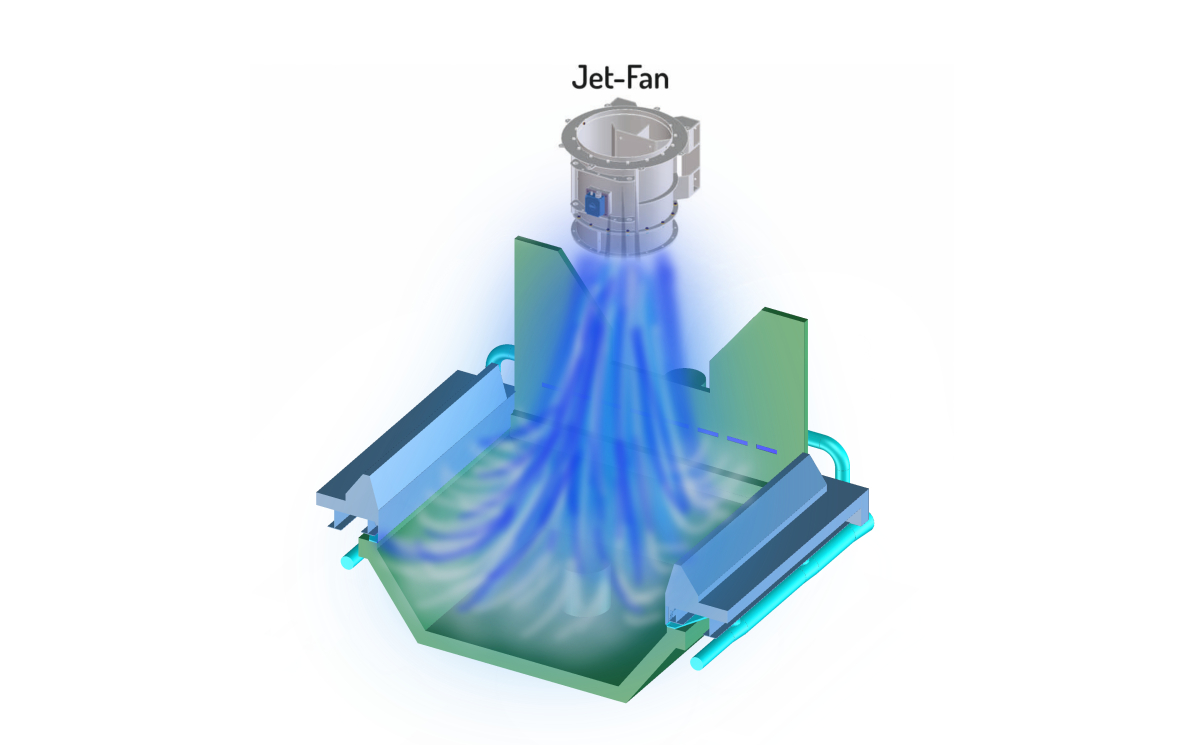

1 The emission capture solution was simulated and optimised using a CFD (Computational Fluid Dynamics) simulation with ANSYS software

1 The emission capture solution was simulated and optimised using a CFD (Computational Fluid Dynamics) simulation with ANSYS software

© DFT GmbH

Task and challenges

Fine dusts, so-called PM10 dusts, which are produced during the loading of the mined bulk material into the downstream process, pose a considerable risk to the health of workers and the environment. The new plant must therefore be planned and equipped in such a way that these emissions are efficiently captured and controlled.

Innovative solution through CFD simulation

The entire emission capture solution was simulated and optimised using a CFD (Computational Fluid Dynamics) simulation with ANSYS software. The simulation enabled precise planning and customisation of the new dedusting system to ensure maximum efficiency and effectiveness.

2 Functioning of the Jet Fan

2 Functioning of the Jet Fan

© DFT GmbH

The main components of the new system include

Bag filters for dry dedusting: These filters are designed to efficiently clean the dust loaded exhaust air of solid particles before the air is fed into the environment.

Jet fan: These high-performance fans direct the resulting emissions towards the suction hoods to minimise their dispersion.

Wind curtain: This device at the gates of the crusher hall serves to minimise the influence of wind on dust distribution and prevents the distribution of dust through cross-flows and turbulence.

Wind fences: These fences reduce the wind speed in the vicinity of the loading station and the lorries, further reducing the influence of the wind in these areas.

Advantages of the new dedusting system

The implementation of this modern dust extraction system has numerous advantages. On the one hand, the health risks from respirable dust are reduced by reducing the emissions. Secondly, the system contributes to compliance with strict environmental protection regulations by minimising dust emissions.

In addition, the efficiency of mining and processing the copper ore is increased as the operating conditions are optimised and disruptions caused by dust pollution are minimised. This not only ensures continuous production, but also strengthens Chile’s position as a leading copper supplier on the global market.

The successful realisation of this project could serve as a model for similar projects worldwide and shows how technological innovations can contribute to solving complex industrial challenges.