Higher ore production with lower material disposal cost

The initial problem: High costs in the waste disposal process with reduction in mine productivity

Ellatzite-Med AD is one of the largest copper extraction mining companies in Bulgaria and Europe, managing the extraction and processing of copper porphyry with silver and gold ore content at the Etropole Mine and the crushing and flotation facilities of Mirkovo. Over the years they have carried out various projects and substantial investments in the construction of installations and technological equipment, with the aim of ensuring the company’s long-term operation and to improve the financial and technical parameters of mineral extraction and processing of copper ore.

The project carried out by INELAS through its exclusive distributor in Bulgaria, Greece and North Macedonia, GEOTRADING AG, for the installation of the polyurethane inner-lined pipe from the enrichment factory to the Benkovski landfill in the town of Mirkovo, arose from the need to replace the pre-existing line of steel, rubber and polyethylene pipes, which caused many problems and decreased the profitability of the mine. This was mainly due to the need to make frequent shutdowns to replace worn or broken pipes, which caused high maintenance costs in the form of personnel and materials and, crucially for the mine, decreased pipe flow and consequently the ore production.

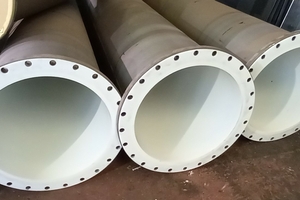

Proposed solution by INELAS: Internally inner-lined INAPRENE® Polyurethane pipes

INELAS’ experience of more than 50 years provides it with in-depth knowledge of its clients’ operations, which allows it to offer them the best advice in choosing the optimal solution to improve their material management processes in the mine, as well as providing them with the best technical support. As the only possibility to solve the mine’s problems with the material disposal process, INELAS proposed and executed a complete replacement of the existing piping lines with polyurethane innerlined pipes of the highest quality and performance capacity.

Compared with steel, polyethylene or rubber pipes, polyurethane inner-lined pipes have a higher ability to withstand high pressures, a higher elasticity and a lower friction coefficient, which more than meet the high requirements of the project in terms of fluid speed, flow rate and solid concentration.

But it is the extraordinary resistance to abrasion that makes the big difference in terms of the duration of the pipes, which is the solution to Ellatzite Med’s problems. And especially the INAPRENE® polyurethane, which is self-formulated by INELAS with the special optimal formula for this application, after more than 50 years of continuous research.

Advantages for Ellatzite Med

The most substantial change that Ellatzite Med has achieved with this investment is to greatly increase the duration of the pipes in the waste line. This has meant eliminating reactive shutdowns due to breakages and greatly reducing the frequency of scheduled maintenance shutdowns with the consequent reductions in maintenance and personnel costs to practically zero, as well as eliminating the cost of replacement material. Other clear benefits of the new pipes are their great safety, reliability and tightness, with a clear environmental improvement.

All this has resulted in a higher performance of the mine operation and therefore a substantial increase in its profitability.

More than 10 years of increased production and reduced cost

After the last annual inspection, it has been verified that, after more than 10 years of operation for 365 days a year and 24 hours a day of the first section of the pipe, the internal coating of all the verified pipes has not suffered any wear due to abrasion, or the one they have suffered is negligible, even in the most aggressive sections (the most inclined tracts, curves, T’s, etc.). The inside diameter of the tubes remains exactly the same as when they were laid and there is no sign of rust or corrosion and the flange welds are in perfect condition. Likewise, it has been possible to conclude that the properties of the INAPRENE® TF-85A polyurethane remain unchanged. The measurement of polyurethane hardness has not changed during all these years, giving exactly the same result as after its manufacture and analysis of physical properties.

According to information from the client, in many sections the steel pipes without polyurethane lasted barely a year, while the rubber ones rarely lasted two years, the same as the highest quality polyethylene pipes.

The experience of INELAS is being corroborated once again with the experience in the Ellatzite piping line: the pipes can last up to the life of the mine with little or no substitution of any element. With this project, INELAS has achieved total customer satisfaction, with a unique product in the market for the solution of problems in the transport of abrasive solids in mining.