KW-Generator GmbH

A special feature is that the KW generators are designed with a high IP67 protection rating, which stands for dust and water resistance as well as vibration resistance. In addition, the system is tested to -40°C as standard. They are therefore ideally designed for use in the harshest conditions and can withstand even extreme environmental stress. As an experienced industry expert, Michael Werner, Managing Director of KWG, knows: “The user must be able to rely on the smooth operation of their system, which is why our generators permanently withstand external influences such as water, dust and vibrations.” Inside, Michael Werner continues, the winding and the ball bearing are completely protected. The generators are cooled exclusively via the cooling fin on the housing. A special boost control of the digital voltage regulator ensures remarkably high starting currents.

A brushless design

Basically, the KW generators guarantee maintenance-free operation for up to 20 000 hours. The high-performance ribbed contour, combined with the sophisticated geometry, sets new standards in terms of performance and noise emissions – with the same construction volume and identical size compared to previous models. In addition, the brushless generators are equipped with a digital generator controller with CAN SAE1939 and True RMS measurement. The fact is that the latest generation of KW generators offers an increase in performance of up to 20 % with the same iron length. Also important: Integrated Temperature Management ensures that the average values of all winding temperatures in the air flow are determined and made available in the controller to calculate the maximum temperature for safe operation.

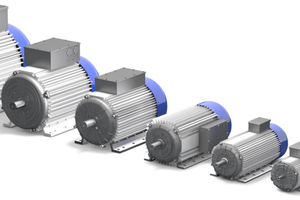

A broad product range

The manufacturer currently offers various generators from 5 to 550 kVA in sizes 132, 160, 200, 250, 280 and 355. Regardless of size and design, all generators are synchronised, electronically controlled and brushless. They also feature CAN interfaces and insulation monitoring. The “Synchronous Generator BG 355” model, for example, has an integrated generator controller with standard CAN SAE1939 and offers universal flange connection options. The system is 4-pole: 225 to 550 kVA at 1500 rpm. With this brushless and self-excited solution, all standard voltages are also available in three-phase. According to the manufacturer, the user can also rely on maintenance-free operation for up to 20 000 hours. This high-performance unit is designed for use under extremely harsh conditions, for example in the construction and railway sectors or in industry.

Focus on high production quality

A look behind the scenes reveals that KWG thrives on the fusion of tradition and modernity. On the one hand, the company utilises its many years of expertise in in-house production and manufactures its complete ready-to-connect systems with control cabinet, touch control unit and insulation monitoring entirely in-house. On the other hand, KWG is regarded as a pioneer and co-thinker that designs new solutions with proximity to the user. In addition, the company has made important investments in recent years: the production lines are partially automated with networked automatic test benches. Among other things, a new logistics centre was completed in 2022. The high-tech building has a large number of newly created, process-optimised pallet bays, which has significantly increased efficiency. “Our declared aim is to launch new solutions that have been developed by professionals for professionals,” says Michael Werner. “From the initial idea at the desk to the final series production, we are in constant dialogue with those who use our products on a daily basis.”

It should be added at this point that KWG’s generators are manufactured in accordance with DIN ISO 9001:2015 and DIN ISO 14001:2015. KWG also supports the development of customised generators and control systems by providing 2D and 3D data so that data can be exchanged quickly and easily with customers and suppliers.

“Road to bauma”: What 2025 will bring

KWG is currently in the hot phase: the company already took part in bauma in 2019 and 2022, where it was able to impress visitors with its brushless and variable-speed generators in particular – which attracted the interest of manufacturers of mobile crushing plants in particular. Due to the solid construction, the high quality standards and the performance of the KW generators, KWG’s solutions are located in the premium segment, and the unit price is correspondingly higher. However, and this is particularly evident when used in harsh conditions, the additional costs quickly pay for themselves thanks to the durability and reliability. KWG will be presenting its portfolio at the upcoming bauma 2025 in April in Hall A5, Stand 141. In addition to Managing Directors Michael Kurz and Michael Werner, Sales Manager Patrick Kreeb and Technical Manager Matthias Werner will also be on site in Munich to inform trade visitors about the most important new developments and the existing portfolio.

Booth A5/141