Crushed slag & concrete are 100 % recycled

1 The RM 100GO! crusher crushes concrete and slag

1 The RM 100GO! crusher crushes concrete and slag

© Rubble Master

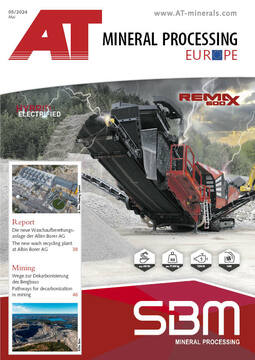

Crusher scores with versatility and sustainability

The RM crusher was ordered and put into operation over four years ago. It was particularly important to the customer to acquire a crusher that is suitable for a wide range of applications. The RM 100GO! can undoubtedly fulfill this requirement. The impact crusher not only enables the crushing of concrete from the demolition of old, rigid pavements, but also the recycling of other regionally available materials such as slag. The outstanding quality of the machine and the favorable financing conditions offered by RM dealer COVEMA ultimately convinced the customer to purchase the crusher. “Thanks to the extreme versatility that the RM 100GO! crusher offers in recycling locally available materials, we are able to achieve the highest level of environmental commitment on the Argentinian road market,” confirms the customer.

2 The throughput capacity is 150 t/h

2 The throughput capacity is 150 t/h

© Rubble Master

What to consider when crushing slag

Slag is created during the production of steel and consists of mineral components and other elements that are removed from the metal ore during the melting process. Slag also usually contains iron, which can cause damage in the crushing chamber if the wrong crusher is selected. The advantage with the RM 100GO! crusher is the RM Release System (impactor opening to remove blockages in the impactor), which opens if pieces of iron are present in the material being crushed, thus preventing damage in the crushing chamber. Nevertheless, large pieces should still be sorted out or pre-crushed before feeding, as iron parts that are too big can cause damage to the crusher despite the Release System.