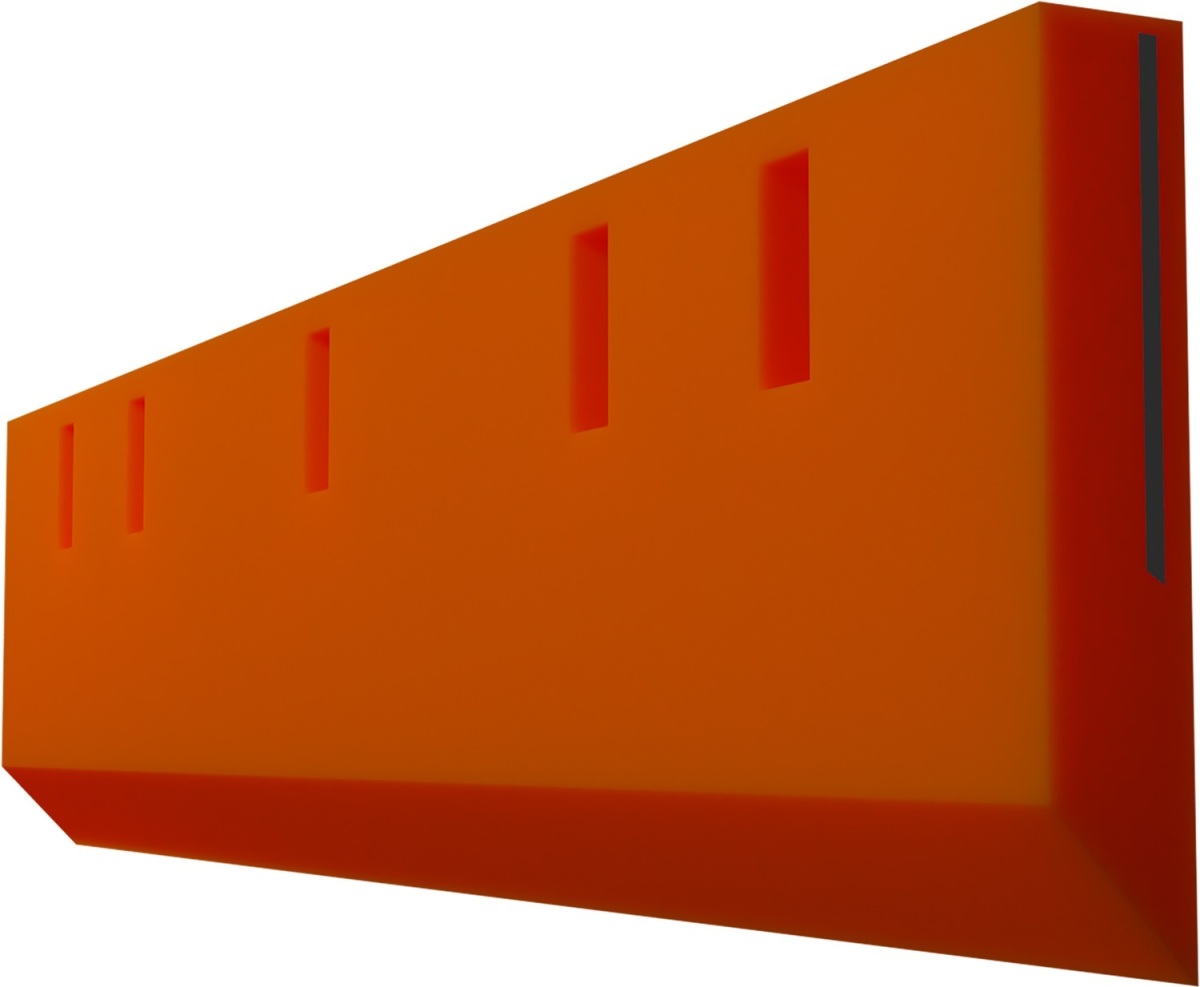

Conveyor wear liner engineered to protect chutes and extend skirt life

1 Martin® manufactured canoe liner with 45º trough angle and adjustable mounting height

1 Martin® manufactured canoe liner with 45º trough angle and adjustable mounting height

© Martin Engineering

“This is a shift in the engineering and role of wear liners,” said Dave Mueller, Manager of Conveyor Products for Martin Engineering. “Like most conveyor components, the design has evolved into a component that is more effective, safer to maintain and more reliable.”

Previously, most wear liners were sheets of steel welded onto the internal chute wall of the conveyor loading zone. These protected the wall from the punishing effects of splashing, shifting and abrasive material. But since they are wear parts, periodic replacement of these early designs involved enclosed chute entry and hot work using a blow torch, which required certification and supervision, while running the risk of igniting explosive dust. The steel plates generally did not effectively protect the rubber skirt seal, leading to more frequent skirt replacements. Moreover, the wear liner’s position often left a gap between the liner and the skirting, which captured small lumps of material that could damage the belt. These design issues resulted in excessive downtime, premature equipment replacement and extra labor to monitor and maintain.

2 Cut to length, the liner easily retrofits onto existing conveyor systems for superior sealing in punishing applications

2 Cut to length, the liner easily retrofits onto existing conveyor systems for superior sealing in punishing applications

© Martin Engineering

The Martin Manufactured Canoe Liner is an engineered urethane strip molded directly around a protective steel plate. The unique approach avoids the bonding issues common to previous designs, preventing urethane separation from the plate that could damage the belt and enclosure. Each section has a series of 51 mm long bracket holes for vertical adjustment. The bottom “belt side” of the liner is cut to an optional 20º, 35º, or 45º angle to maximize belt sealing and protect the softer material of the skirt seal from premature wear. Depending on the weight and abrasiveness of the conveyed material, customers can choose a urethane thickness of 33 to 51 mm.

Delivered in storable cartridges 1219 mm in length, the units can be cut on site to match the needs of the chute. The cartridges can also be installed vertically on top of one another to accommodate taller chute walls or raised enclosures. Like the lower sections, the upper units can be adjusted as well. As material gradually erodes the Manufactured Canoe Liner, the bottom trough angle continues to protect the skirting. If there are significant gaps between the belt and liner, each individual cartridge can be adjusted by a single technician using a socket wrench. Replacement is easy by simply removing the worn units, mounting each new cartridge, and cutting the end piece to fit. This reduces what used to be a one or two day job to one to two hours.