Bosch Engineering

Bosch Engineering presents assistance systems for deep and open cast mining machinery at steinexpo 2023.

Working with mining machinery is associated with a wide variety of hazards. Collisions between excavators, dump trucks, or caterpillar trucks and people or obstacles are a common cause of accidents. To avoid accidents the drivers must always have the entire area surrounding the vehicle in view. This causes constant stress and leads to physical strains. Electronic assistance systems like those from Bosch Engineering can help to alleviate this: when they identify persons or objects within the detection area around the vehicle, they issue corresponding warnings and show the exact position on the display, thus allowing the machine operator to keep a close eye on any blind spots. “Our assistance systems thus make an essential contribution to improving safety in the mining industry, make work easier for the machine operators, and increase the efficiency of work,” explains Philipp Kurek, who is responsible for off-highway solutions at Bosch Engineering GmbH

![]() Assistance systems for visual object recognition ensure more safety in operation

Assistance systems for visual object recognition ensure more safety in operation

© Bosch

Flexible modules for assistance systems

Bosch Engineering has therefore developed a modular system with tailor-made systems and sensors for extensive assistance functions especially for particularly demanding mining applications. The sensor concept includes a variety of ultrasonic and radar systems, as well as a camera system, that can be configured flexibly, allowing them to be tailored to the requirements of the specific application and assistance function. Bosch Engineering draws on its expertise and proven key solutions from the passenger car domain and adapts these technologies specially for use in the off-highway segment. The result is that the systems combine a high level of functional safety with exceptional robustness, even under the toughest of operating conditions. Due to the connectivity with the vehicle electronics required for reliable functioning, the assistance systems from Bosch Engineering are designed as a solution for original equipment (OE). The exception is the camera system, which is also available as a retrofit kit. This includes all of the components for retrofitting, including the wiring harness, display, and camera mount. The system features a display with intuitive operation and easy commissioning even in existing vehicles.

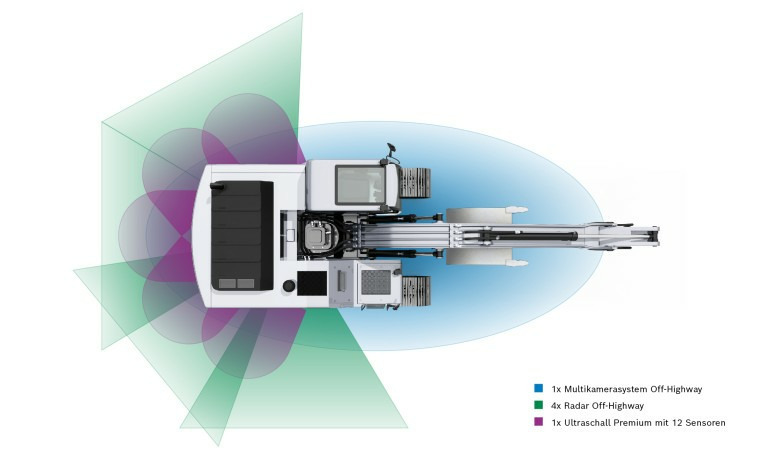

Sensor ranges for excavators

Sensor ranges for excavators

© Bosch

On the way to fully automated mining

Modern assistance functions are generally designed to warn the driver about hazards. The advanced ultrasonic system from Bosch Engineering goes one step further. If obstacles are detected in the vehicle’s path, the system will be able to trigger a stop signal to the vehicle control system in the future, bringing the machinery to a stop in dangerous situations. Machine manufacturers can thus integrate a sophisticated emergency braking assistance function into their application as a proven and reliable “plug-and-play” solution without having to use their own development capacities. Bosch Engineering is also already working today on the automated and connected mining machinery of the future, which performs its work fully automatically without any manual intervention required on the part of the machine operator. The second-generation off-highway robotic controller (ORC2) provides high-performance control unit hardware for partial and full automation. The system offers high computing and storage capacity, with sufficient capacity for demanding automation functions. Standardized interfaces allow for quick and easy integration into the vehicle electronics, and preinstalled drivers make it easy to integrate the sensors.

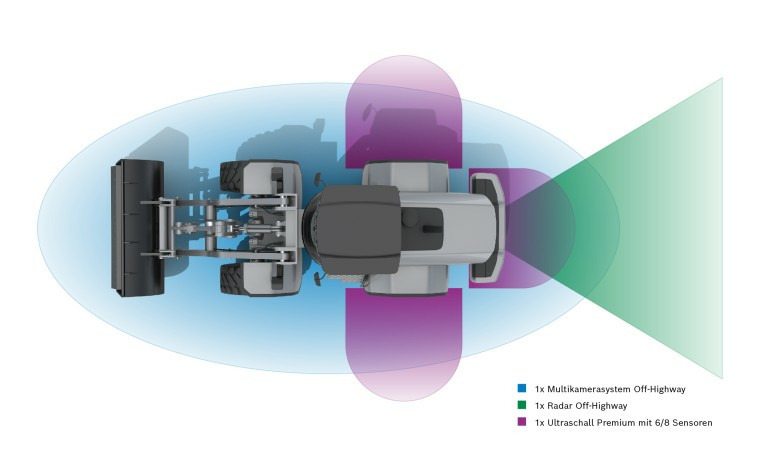

Sensor ranges for wheel loaders

Sensor ranges for wheel loaders

© Bosch

Peak Evolution – electric at high altitude with Bosch components

The second megatrend in mining machinery is alternative powertrains. Bosch Engineering offers electric drives for a wide variety of different off-highway applications here. “All components of the electric drive system offer very high profitability, robustness, and durability because they are based on the tried and tested technologies that Bosch has been using successfully in the commercial vehicle sector and other commercial applications such as construction machinery for many years,” says Kurek. The Swiss expedition team members of Peak Evolution are also relying on the dependability and performance of the electric components from Bosch Engineering for their ambitious world record attempt. The team plans to reach the peak of the 6893-m-high Ojos del Salado volcano in Chile with an electric off-highway vehicle. “The grand finale will be in December 2023, we will slowly work our way upwards over several days. That would be a new altitude world record for vehicles – the record currently stands at 6694 m,” says Patrik Koller, cofounder of TERREN Electric Drive Systems and Peak Evolution. Among other things, Bosch Engineering is supplying the two 400-volt electric motors and the appropriate inverter for the drive system in the expedition vehicle. Bosch Engineering experts are also supporting the Swiss team with integration of the drive into the vehicle and with application of the system to the specific operating conditions for the high-altitude expedition.

Booth D9 and the Quarry Vision 2 open space at steinexpo 2023 will be the meeting point for more information about the Bosch innovations and the Peak Evolution expedition vehicle. Experts from both companies will be on hand there to talk about the mining machinery of the future as well as the expedition vehicle.

Booth D9