Sandvik partners with Boliden on 3D printing trial

1 Additive manufacturing of parts and components shows a lot of potential for reducing the carbon footprint within the supply chain

1 Additive manufacturing of parts and components shows a lot of potential for reducing the carbon footprint within the supply chain

© Sandvik

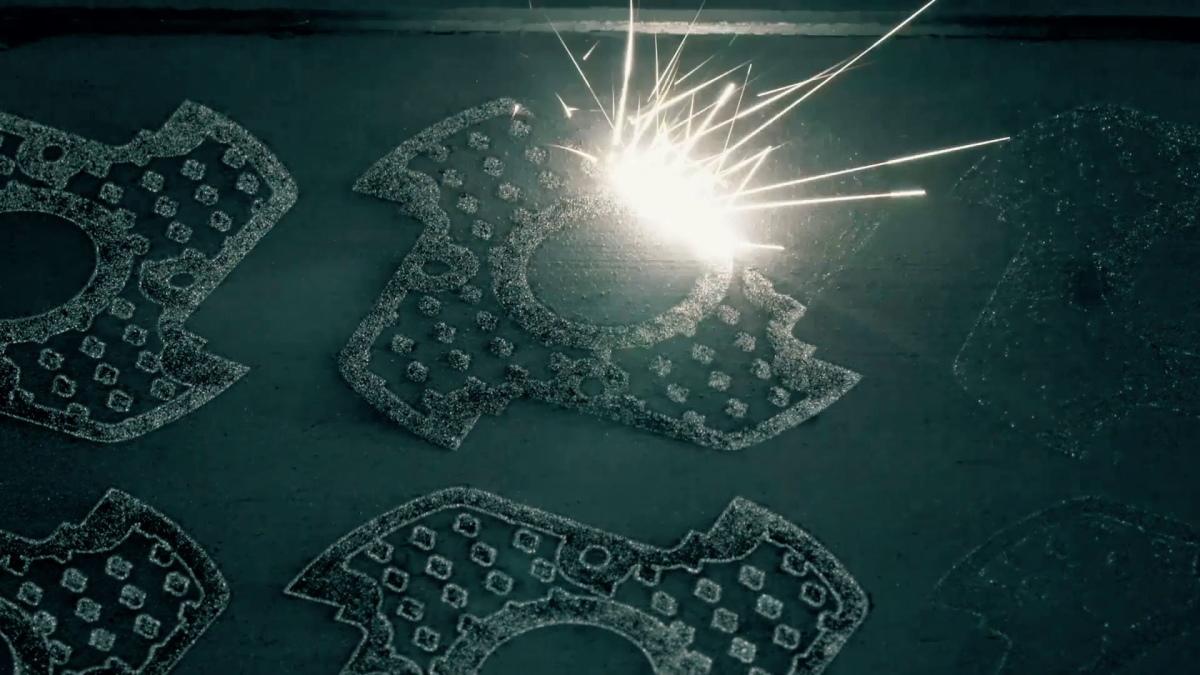

Sweden has a long and noble history of mining, with evidence of human activity dating back to prehistoric times. But old does not mean primitive, as a trial of cutting-edge technology between Sandvik and Swedish mining and metals giant Boliden shows. Additive manufacturing – or 3D printing as it is more commonly known – is maturing fast, and has progressed from printing plastic components to now being able to print ceramics and metals. To discover the potential of the technology, Boliden has teamed up with Sandvik to run a trial that will see machine parts printed digitally and installed on underground drill rigs.

2 Boliden has partnered with Sandvik to launch a trial in which machine parts are digitally printed and installed on underground drilling rigs

2 Boliden has partnered with Sandvik to launch a trial in which machine parts are digitally printed and installed on underground drilling rigs

© Sandvik

Proof-of-concept

The trial with Sandvik involves a set of specially redesigned components printed digitally at a Sandvik-managed facility in Italy, with their performance being monitored on machines in Boliden’s underground mine worksites – first in Sweden, then in Ireland. At least in theory, the 3D metal parts could perform as well – or even better – than traditionally manufactured items. The first components have just been put into operation in the Garpenberg mine, with performance still to be evaluated.

“Additive manufacturing shows a lot of potential, both in reducing carbon footprint within the supply chain, through reduced or eliminated need for transport and storage of parts and also shorter delivery times. This trial will give us a deeper understanding on how we can move forward and develop our business in a competitive way,” says Ronne Hamerslag, Head of Supply Management at Boliden.

Local manufacturing is ‘the future’

3D printing is an exciting prospect for OEMs too, as Sandvik’s Erik Lundén, President, Parts & Services at Sandvik Mining & Rock Solutions explains: “Mining equipment can last up to 25 years – and needs to be supported throughout that time – even in the most remote of locations. We have many different SKUs (stock keeping units), and from an inventory point of view we can’t tie up the capital that keeping all these parts in stock would entail. 3D printing of parts locally offers us the prospect of not only getting parts to the customer much faster, but doing so far more sustainably.”

Although in theory any part could in future be 3D printed, it is likely to be maintenance and repair operating items that are the first to get the additive manufacturing treatment, such as the bushes, brackets, drill parts, etc. that customers need to change every 3000 to 4000 hours. But printing of the parts is only one part of the puzzle that the trial with Boliden is trying to solve. Another is working out the future business model for 3D printed parts. Who does the printing – the OEM, the miner, or a third-party printing company? What will the costs be? What about intellectual property rights, warranties and liabilities? All these things – and more – need to be resolved in the development of a 3D printed future.

Game changer for parts business

“If you ask me, it’s the most exciting thing that’s happening in the supply chain,” says Boliden’s Hamerslag. “Its efficiency, speed and climate friendliness mean that we have to investigate additive manufacturing closely. We are only at the proof-of-concept stage with Sandvik right now, but it’s already clear that it could become a game-changer for the spare parts business in mining – for both miners and equipment manufacturers.”