White powder and black rock

At POWTECH 2014 the BEUMER Group, a full-line supplier for filling, palletizing and packaging technology, will be presenting its expertise. Visitors will learn about conveyor systems, the warehouse management system and BEUMER’s extensive customer support. Whether construction materials or chemical products are needed – the user can get everything from a single source.

Depending on the operating environment, method of handling and anticipated application, the behavior of powders and bulk materials can change completely in conjunction with certain materials. Behavior can depend on the particles’ size and form, bulk weight, compressibility, cohesive strength, moisture, oil content and type of reaction to atmospheric conditions. This affects the flow behavior, which in turn has a significant effect on the correct design of conveyor systems and filling, palletizing and packaging equipment. BEUMER plans, builds and installs systems which are matched to the user’s individual requirements down to the last detail.

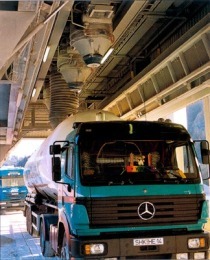

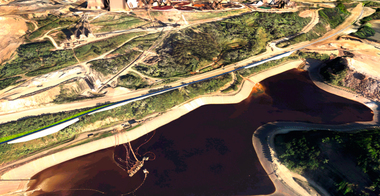

With its belt conveyors, the BEUMER Group supplies economical and sustainable solutions for the conveying of bulk materials. The curved belt systems are produced in an open design as troughed conveyors or in an enclosed version as tubular belt conveyors. They can be optimally matched to the environment and overcome long distances and large height differences. This is ensured by their optimum line through the terrain and tight horizontal and vertical curves which can also be laid above one another in the route of the conveyor. The strength of the BEUMER Group is its ability to combine individual machines and systems by means of intelligent automation for greater efficiency. The BEUMER Group delivers filling, palletizing and packaging equipment from a single source as a systems supplier.

The BEUMER fillpac bagging system can be incorporated flexibly into existing packaging lines. It is equipped with a calibratable scale. The electronic weighing unit ensures that the fillpac always achieves accurate filling quantities. Special software enables the weigher to communicate continuously with the filling spouts. This enables users to get the best out of their packaging lines, as it is not necessary to reject bags with incorrect weights from the process.

BEUMER has completely revamped the BEUMER paletpac high-performance layer palletizer in order to stack paper, PE and PP bags on different sized pallets flexibly, accurately and stably. BEUMER has completely overhauled this product so that it works even more efficiently. Users benefit from improved accessibility, shorter installation time, greater flexibility and therefore lower costs. The palletizer can be fitted with a double belt turning mechanism which allows bags filled with bulk materials with special flow behavior to be stacked on pallets gently, quickly and accurately. BEUMER’s Customer Support specialists can easily retrofit existing machines with this solution.

BEUMER also offers the robotpac, a space-saving, fully automatic articulated robot which is able to perform complex palletizing and depalletizing tasks reliably and efficiently. BEUMER has added a new machine to its stretch hood series for efficient packaging of palletized stacks. As part of this work, it redesigned its high-performance packaging system from the bottom up. During development, the company’s experts analyzed and optimized different components.

BEUMER has also developed a Warehouse Management System (WMS). This system fulfills all the main requirements of the bulk materials industry, such as the storage of sensitive substances, batch tracking and space-saving and cost-efficient warehouse management. The WMS has an interface to all common ERP systems. Warehouse management, the material flow system and process control of the individual machines are incorporated. The user therefore has a continuous overview of his production and storage facilities at all times and can match them to the prevailing requirements. Visitors to the trade fair can learn all about BEUMER’s comprehensive customer support.

Hall 1, Stand 135