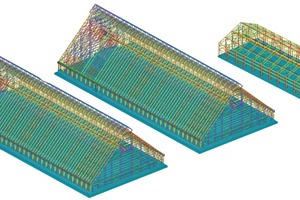

Warehouses for fertilizer plant in Saudi Arabia

In November 2014, Intecsa awarded the contract for the steel construction plant in six large warehouses, including conveying systems, to the Unger Steel Middle East FZE (Fig.). The work on the project is planned for the period between May, 2015 and the end of July 2016, i.e. the large halls will be realized with a construction period of only 14 months, using about 20 000 t of steel. The Kingdom of Saudi Arabia boosts the further development of the mining sector which is to be expanded to become the third pillar of the economy following the oil and petrochemical industry. Therefore, in Waad Al-Shimal Mineral Industrial City, a new fertilizer plant is being built, which, after its completion, will have a production capacity of 3 million t/y. The total amount of investment in this challenging large-scale project in the North of Saudi Arabia amounts to approx. 530 million €.

For the construction of the warehouses with an installed length of 103 760 m² and the impressive total length of almost 1.5 km, Intecsa Industrial relies on the Austrian Unger Steel Group, which has been working in the United Arab Emirates since 2007 with the Unger Steel Middle East FZE delivering European top quality into the entire Arab region. The six large warehouses with a length of 110 to 276 m, a width of up to 72 m and a height of 45 m are being built as a self-supporting structure to provide a large storage area without restrictions. Following the timely completion and handover in July 2016, the halls will be used for the storage of potash and phosphate; sand trap lamella and ridge ventilation ensure natural air circulation and cooling. The Unger Group was also entrusted with the supporting steel structure, the construction and erection of the conveyor belts arranged under the roof ridge as well as the steel structure of the conveyor system, which leads from the manufacturing plants to the new warehouses and further on to the port.

//www.ungersteel.com" target="_blank" >www.ungersteel.com:www.ungersteel.com