Two products from a single grinding mill

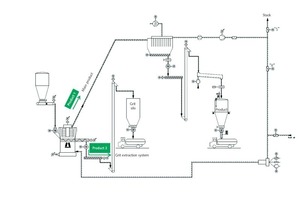

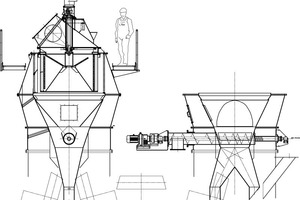

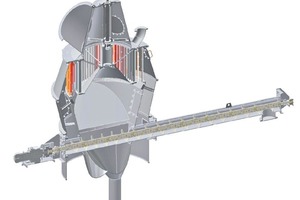

Simultaneous production of fine product and grit in one vertical roller millSummary: Loesche mills have become firmly established in the grinding of industrial minerals, such as limestone, bentonites and dolomite. The applications for ground limestones of various particle sizes are both broad and diverse and include, for example, the power generation, plastics, building materials and refractories industries, paint and exterior render production and also agriculture, environmental protection and highway construction, to mention only a few. The demands made on product quality and the necessary levels of fineness have risen steadily in recent years, due to the diversity of the applications for these materials. Plant operators are correspondingly obliged to modify their product portfolios to meet customer demand. Loesche has therefore reacted to these new requirements with the development of an industrial minerals mill with throughputs of 5 to 100 t/h featuring an integrated grit extraction screw.

1 Introduction

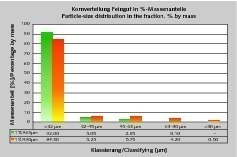

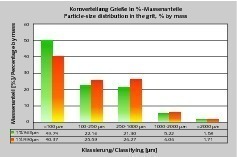

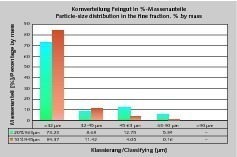

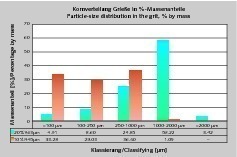

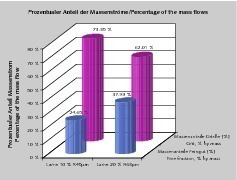

Incorporated into the standard configuration of the Loesche vertical roller mill, the grit extraction system makes it possible to produce not only fine products (< 100 µm) but also a further product (> 100 µm) simultaneously. In order to quantify the mass flows and particle-size distributions in the fine product and the grit, Loesche has conducted test measurements in co-operation with the following limestone-processing companies:

• Karl Kraft Steinwerke in Heidenheim/Germany

• Kilwaughter Chemical Co. Ltd in Larne/Ireland

The tests performed in these two plants demonstrate the...