Shaft hoisting plant from Siemens

The Chinese Yitai Group has awarded Siemens Drives Technologies an order in the double-digit million range to install two shaft hoisting machines in a new coal mine. The drives for the Hong Qing He project in Inner Mongolia will be the biggest hoists in the world to feature a motor integrated in the drum.

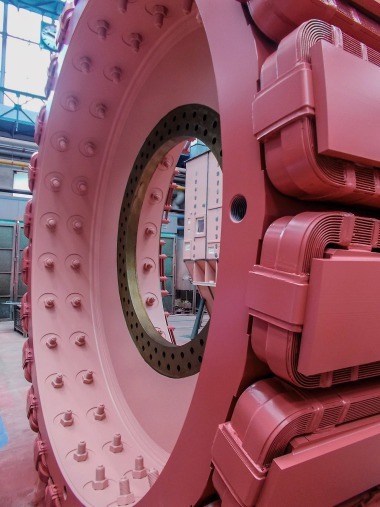

The extremely compact design of the integrated hoisting machines from Siemens will help the Yitai Group to reduce their investment costs when building the new colliery. The carbon footprint of integrated drives is smaller than that of conventionally designed plant. The project marks the first cooperation between Siemens and the Yitai Group. Siemens will supply two production hoists with integrated 9 MW motors. This means the installation will include the biggest mine winder motors ever supplied by Siemens.

In order to transport personnel and equipment underground for this high capacity, Siemens will additionally equip the mine with two service hoists, each powered by a conventional 3.8 MW motor and a 355 kW motor, as well as by a SM150 and a S120 Sinamics converter. Siemens is also responsible for the entire automation control and monitoring systems as well as for all the medium-voltage and low-voltage control panels, the shaft signaling equipment, the loading and unloading facilities and spare parts as well as for commissioning and training. The start of operations is scheduled for early 2015.