Schmersal presents new range of belt alignment switches

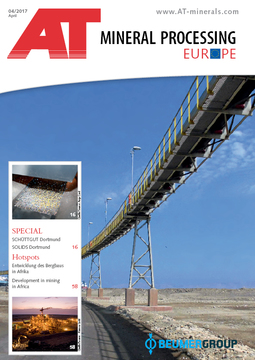

The Schmersal Group is extending its range of belt alignment switches to include new models and now offers a complete range of products for monitoring conveyor systems with a wide variety of options to cover different requirements. At the same time, the new belt alignment switches in this range are longer-lasting, enable reduction of failures and downtimes and thus improve plant availability. Schmersal is presenting the complete product range for the first time in May 2017 at the Solids Trade Show in Dortmund/Germany.

Conveyor belts can move from their planned track, which can cause a great deal of damage. Belt alignment switches are therefore used to detect belt alignment and switch off the belt. The product range from Schmersal consists of three series which are perfectly adapted to the relevant belt speeds of the conveyor systems. At higher speeds, switch models can be used in which the belt alignment rollers have a greater diameter. This means a lower number of revolutions which results in reduced wear. At the same time, most options have an advance warning function to enable preventative maintenance.

The Economy Range is designed for small conveyor belt systems with textile belts and a maximum belt speed of 1 m/s.

The Standard Range is ideal for medium-sized conveyor belt systems which are longer, with steel conveyor belts and belt speeds of up to 6 m/s. The new T. 454 series switches have two switching angles, each with two channels, which are also used for advanced warning and switching off if the belt becomes misaligned. Based on staggered contacts, there is an advanced warning as of a 10° misalignment, for example, with the belt switched off if it reaches 25°. The T. 454 series is available with an optional Dupline installation bus to enable time-saving trouble-shooting. The stainless steel belt alignment rollers in the Standard Range are available in diameters of 30 and 50 mm.

The Performance Range can be used in very high-speed conveyor belt systems. The belt alignment rollers in the T 250 range are made of stainless steel. With a roller diameter of 50 mm, they are suitable for belt speeds of up to 6 m/s and the 90 mm diameter option can even handle 11 m/s. The Performance Range has the standard advanced warning functions as the Standard Range.

Complete solutions from a single source

Based on a global market cooperation, Schmersal and Coal Control offer integrated solutions from a single source for safe and productive conveying of bulk goods. The product ranges from both companies cover both machine/occupational safety and investment protection, complement each other perfectly and represent in this combination a unique selling proposition on the global market

Stand: K 22 – 5

//www.schmersal.com" target="_blank" >www.schmersal.com:www.schmersal.com