Safety in explosion-risk areas – using ATEX equipment

Potentially explosive atmospheres can be caused by combustible dusts or combustible gases. On the action of an ignition source, this atmosphere can ignite, resulting in an explosion. Ignition sources include electrically generated sparks, electrostatic discharge sparks, hot surfaces or fire, flames and glowing heat. To prevent an explosion, at least one of the three factors (air, combustible dusts/combustible gases, active ignition sources) must be minimized or eliminated. An explosive atmosphere can therefore be prevented by avoiding dust deposits, e.g. regular cleaning with effective industrial vacuum cleaners.

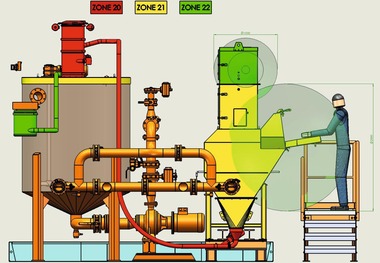

Wieland Lufttechnik supplies a range of industrial vacuum cleaners and stationary vacuum systems that can be used easily and efficiently for cleaning equipment and floors, even in explosive atmospheres. Various models are available that comply with the requirements of Atex 95 (EU directive 94/9) for application in zones 1, 2, 21 and 22. All equipment is also suitable for health-hazard dusts in the dust classes M and H (EN 60335-2-69). Atex 95 applies to equipment and protective systems for their intended use in explosion-risk areas and for equipment installed/used outside of explosive risk areas but which are subject to explosion risks. If vacuuming of an ignition source cannot be avoided, Wieland Lufttechnik offers stationary vacuum units as additional dust explosion protection units (dust explosion relief, dust explosion suppression or explosion pressure-shock proof design and construction).

Hall 5; Stand I 15