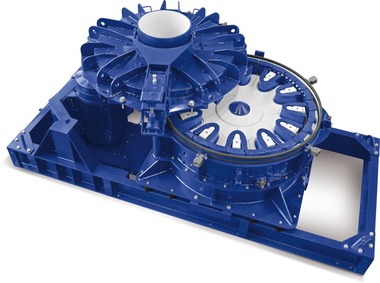

Rotor centrifugal crusher RSMX with “TwinDrive” from BHS-Sonthofen to cubify sand

Stevin Rock’s limestone quarry in the northern Al-Hajar Mountains in UAE is the third-largest in the world. Situated just two hours’ drive away from the region’s boomtown, over 60 million tons of high-quality sand-lime blocks are extracted here every year, the majority of which are processed on site. The company, which was established back in 1975, enjoys an excellent reputation in the Gulf region, especially as a supplier of high-quality sands – a raw material that is in urgent demand in Dubai for the construction of skyscrapers such as the Dubai Creek Tower, which is expected to be 1300 m tall, or the Burj Khalifa, as well as construction of the subway or the international airport.

However, Stevin Rock does not just simply mine the coveted material – it manufactures it in a complex, multi-stage process. Cubification put simply: Although the Gulf region is blessed with an overabundance of natural sand deposits, the structure of the sand’s particles means it is suitable for mixing low-quality concrete at most. The high-strength concretes such as those used in the construction of skyscrapers, however, require sands with cubically shaped particles – and these are not found in the region.

Rotor centrifugal crushers ensure the perfect particle finishing

Two ultramodern rotor centrifugal crushers (RSMX) from BHS-Sonthofen have recently started making a crucial contribution to Stevin Rock’s sand manufacturing operation: The limestone extracted in the quarry is first brought in gradually at a size of 5 – 10 mm. The two RSMX crushers with TwinDrive (a double drive) then break it down to a size of 0 – 5 mm, while also turning it into the ideal cubical shape. “In other words, our rotor centrifugal crushers perform the final finishing step,”explains Hans Traut, Area Sales Manager Middle East & North Africa at BHS-Sonthofen. “They put the finishing touches on the sand and ultimately determine the quality of the product. The sand is then washed one final time and that’s it – done.”

Traut has been working together with Stevin Rock for eight years now – but the experts from BHS-Sonthofen have already been working in the region for several decades. 15 mines and multiple dry-mortar plants in the region use BHS Impact Crushers. Traut and his team have long since made a name for themselves as intimate connoisseurs of the diverse rocky landscape that the Middle East has to offer: They have already examined hundreds of tons of samples from different mines across the Gulf region at the technical center at our headquarters in Sonthofen, Germany. How does each rock behave? How does it break up? What flow speed generates the optimum result? Just because rock is a natural material that is never 100 % predictable in terms of its behavior does not exclude leaving as little to chance as possible.

Expert consultation makes the difference

Traut was able to call on this expertise in the case of the rotor centrifugal crushers with the TwinDrive system at Stevin Rock, too. The crushers were adjusted to the customer’s plant and important parameters were defined beforehand so that the two RSMX with TwinDrive actually achieve the desired result: “For example, at 61 m/s, the circumferential speed is comparatively slow,” says Traut. “But if you were to increase it, the result would be too fine.” Alongside the technological expertise, it is this consultation above all that BHS customers value in particular and it ultimately ensures that production runs smoothly from day one of commissioning.

Stevin Rock is no different: The two BHS machines helped the company to produce around 300 000 tons of high-quality sand in the first fourth months alone – and the plant still isn’t even at full capacity. At the moment, only one of the two rotor centrifugal crushers is in operation at a time because there is currently only one washing system connected. A second one is planned, however, meaning production will soon increase even further.

The RSMXs have already proven themselves. They are settings standards both in terms of product quality and the use of wear parts. The latter in particular can become an important cost factor during continuous operation. However, after his first two inspections, Traut was happy to report that there is “zero wear” – thanks not least to the patented, twin-chamber design of the rotor: Every single particle of the input material undergoes extreme acceleration due to the centrifugal force in the rotor and is hurled against an anvil ring that acts as the impact wall. The rock material also rubs and breaks against itself and not – as is the case with competing technologies – exclusively against the metallic wear parts.

BHS-Sonthofen also relies on especially high-quality and durable materials: Special spin profiles made from tungsten carbide protect the RSMX in the area where the finished material leaves the rotor again. “We have constantly improved the design of our rotor centrifugal crushers over the years. Our RSMXs are a unique solution on the market that are characterized by both their precision and their flexibility,” explains Traut. This means that it is not just the degree of fineness in the end product that can be regulated via speed and rotation speed. Traut and his team also provide consultation in regard to delivering and connecting machines in the respective plants, such as screens. At least once a year, Traut also carries out an in-depth on-site inspection on the rotor centrifugal crushers – even during the midnight shift change, if needs be. “This close contact and dialog with the customer is what’s important to us,” says Traut. “Ultimately, a product is being manufactured here that is contributing to literally shaping the future of the region. The sand that our crushers manufacture is used in practically every major construction project.”