Refurbishment of conveyor bridges

More than 40 years ago TAKRAF has supplied the first F60 conveyor bridges. In order to ensure operational reliability and stability for a further long-term use of the conveyor bridges TAKRAF has now developed several modernization and refurbishment schemes.

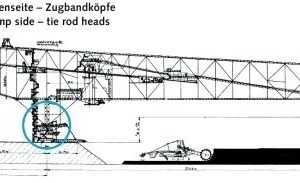

On the basis of comprehensive structural analyses made during the last years, TAKRAF proposes to replace the large equalizer, roller table, ball and socket joint with a diameter of 1250 mm and vertical rail of the overburden conveyor bridge. Another aspect of the proposed modernization program is the replacement of the tie rod heads (Fig.).

The systematical refurbishment of load bearing areas is part of a comprehensive program to increase machine safety for the conveying bridges. The program is developed on the basis of a close cooperation of equipment operator, equipment supplier and governmental mining supervision authorities. The most challenging issue in this program is to divert the enormous supporting forces of 3200 tons of the large equalizer and of 2 x 2100 tons of the tie rod heads in such a way that it will be possible to replace the parts.

The replacement of the large equalizer and the roller table is planned as follows: The overburden conveyor bridge will be positioned according to the technological requirements at the time planned for the complex repair in such a way that the main bridge on the excavator side is lifted by means of the temporary auxiliary construction (support of bridge cross conveyors, shifting and attaching devices for large equalizer and roller table, auxiliary structure) in order to dismantle the roller table and large equalizer with ball and socket joint.

The replacement technology not only includes the manufacturing dimensions of the large equalizer and the roller table and the transport roadway from the Lauchhammer factory to the respective mine site, but also the requirements for the installation on site and the transport route in the opencast mine. For the replacement of the tie rod heads TAKRAF has planned a program that the downtime of the conveyor bridge will be in the range of approx. 10 weeks only. The fabrication of the tie rod heads and the load relieving structure will be prefabricated in the Lauchhammer workshop. To achieve the anticipated 10 weeks downtime the onsite works will be performed in a three shift working scheme, during which time period the dismantling and reinstallation will take place.

//www.takraf.com" target="_blank" >www.takraf.com:www.takraf.com