Premium quality at the highest level

Marking the 125-year anniversary, Berit Müller, Managing Director of August Müller GmbH & Co. KG, provided some information on the background to the company’s many years of success in an interview with the editors of AT MINERAL PROCESSING.

AT MINERAL PROCESSING: 125 years is an impressively long time. What was or is the secret of your success?

Berit Müller: The success of a company certainly depends on various interplaying factors. Important in any case is profound technical know-how combined with many years of experience. Crucial therefore is employee loyalty, and associated with this, very long service of employees with the company, who support the business with their experience.

Good customer support – also after completion of the project – is also a key factor. The feedback from our customers is channelled into projects, and the customers profit in turn from improvements and further developments. In addition, we observe the international market and make specific investments, with the focus on production and assembly, i.e. the needs and satisfaction of our customers are top priority here, too.

AT MINERAL PROCESSING: Would you tell us in more detail about the start of the company?

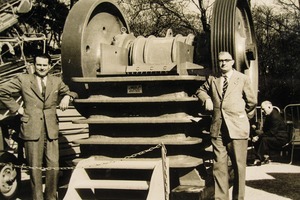

Berit Müller: My great-grandfather founded the company in 1894 in the middle of the town and started off by building water-powered mills. In addition, he built and repaired agricultural machinery – these repairs, by the way, we continue today as a side-line. In 1914, already 20 years after the company founding, the first patents for the Greif stone crusher was registered and granted. This was our entry into this branch, on which we still focus today.

AT MINERAL PROCESSING: What were the milestones in the development of your company?

Berit Müller: These were on the one hand the patents and on the other hand the investments in the expansion of the company and not least the smooth transitions in company management from one generation to the next.

In 1918 and 1919, the sons August Müller Junior and Willi Müller joined the company as apprentices, and in 1924 machine production began at the former second site in the town. In the early 1950s, the current site was developed. In 1960, work started on the construction of a new production facility, which by 1962 was ready, with cranes with up to 20-tonnes lifting weight, for the company to move into. In 1965, my father, Jochen Müller, representing the third generation joined the company, which he took over as managing director shortly after. Under his direction, our office building was extended in 1966, and in 1999 the existing production facility with material warehouse, transverse hall and paint shop was refurbished and expanded.

After my brother, who was set to continue running the business, sadly died in a tragic traffic accident, I myself joined the company. I had the advantage that the then manager of the Export Sales accepted the internally advertised post of plant manager and together with the existing team, who was always behind us, we were able to guarantee the continued operation of the company. When my husband joined the company in 2004, the company’s international sales could be assured so that my father has since been able to retire from active business. He continues to stand by us and support us as an adviser.

When in 2007 we were able to gain a long-standing partner with two colleagues as well as the rights for a machine including replacement parts for our company, we founded a field office on the French border. After this takeover, we realized relatively quickly that we have to extend production. For this reason, we acquired a site in a nearby industry estate, where we planned and built a second production facility from 2008, which was inaugurated in 2009. As the last extension so far, in 2017 we added a storey to the existing office building and doubled the office area.

AT MINERAL PROCESSING: How have you managed to survive the economically difficult years?

Berit Müller: We can bridge difficult times as we operate internationally. We are now represented worldwide with our projects, which we continue to support and optimize after their commissioning. As my father speaks French perfectly, the French-speaking region is a very important market for us, which we have naturally backed up by taking on French employees. My husband and I have been to grow our international business in the English-speaking regions. Moreover, we have representatives, for example, in Poland and Russia, and we supply our machines to Malaysia, Guinea, Saudi Arabia and New Caledonia. Fortunately, we now have many young motivated sales employees, who also travel internationally.

AT MINERAL PROCESSING: What is your company’s core business today?

Berit Müller: Our core business is still in the aggregates industry. Our plants and components can also be found in the cement industry, in mining, in coal, gypsum and nickel extraction, to give just a few examples. True to the motto: Nothing is impossible! We deliver standalone machines for recycling building waste – an industry that is becoming increasingly important for us.

AT MINERAL PROCESSING: What focuses does your product portfolio comprise?

Berit Müller: Besides stationary as well as track-mounted and mobile integrated plants for processing ballast, chippings and gravel, individual components like chain conveyors, push feeders, roller screens, finger roller screens, stepped bar screens or crushers are included in our portfolio.

AT MINERAL PROCESSING: Is there a particular product highlight among these?

Berit Müller: The finger roller screen, which my brother developed with a team, is one of our special products. Müller finger roller screens are used as screens tor process and clean dirty but recoverable material from the primary screening plant. As a result, thanks to the processing of this “screen waste”, the ballast plants obtain much more usable material. In addition, the finger roller screen achieves very good separation and sizing even in bad weather and with difficult-to-screen material from the primary screen.

AT MINERAL PROCESSING: What is your goal for the future?

Berit Müller: Our paramount objective is in any case to assure the future of our company and our employees. Since I joined the company, we have been able to increase the number of our employees from just over 40 to just under 70 employees. With this reserve of long-serving employees and dedicated young employees, we want to get the best outcome for our customers. For this we are investing, for example, in the training of our own young employees, be it as industrial sales executive or as construction mechanic with the option of a dual degree course to study mechanical engineering later. A first graduate is already working in sales.

Overall we want to keep business manageable to remain stable on the market. We are currently well equipped for this: production and assembly are state of the art and the office building has been extended with another storey. The company’s development in recent years, especially after the death of my brother, would not have been possible without the support of our entire workforce. We are a company with a super team and an excellent working atmosphere.

An open day will take place on October 13 in Works II at Rheinwaldstr. 11 in Rottweil, to which all interested are very welcome.