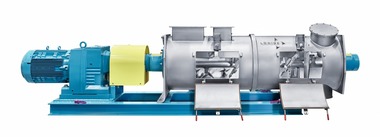

Ploughshare® Mixers for batch and continuous processes

The positioning, the peripheral speed and the geometric form of Ploughshare® Shovels, rotating close to the wall of a horizontal drum, are coordinated in such a way that they counteract the centrifugal force and produce a three-dimensional movement of the product. The so-called fluid bed generated mechanically in this way ensures gentle and intensive mixing of the components. All the product is constantly involved in the mixing process – there is no dead or low-movement zones in the mixing drum. The resultant individualisation of the particles in the mix (fluid bed) ensures the addition of liquids and coating of the particles with ease. Choppers can be used to promote the mixing movement, disperse lumps and achieve granulation processes.

Range of application

Processing powdery, granular and fibrous components

Addition of liquids for moistening and granulation

Processing fragile materials

Addition of viscous materials, for example fat, lecithin and similar in the mix

Production and premixes for frequent change of product

The continuous process is operable at filling grades between 20 % and 50 % without influencing the mix quality. The mixing elements are adjusted in order to achieve constant back-mixing during the whole residence time prior to discharge the mixed product via the outlet for further processing. The adjustment of the outlet size by means of a slide or an adjustable weir has a direct influence on the residence time.

Range of application

Processes requiring high throughputs

Processing powdery, granular and fibrous components

Addition of liquids for moistening and granulation

Compensation of dosing fluctuations

Hall 1/517

//www.loedige.de" target="_blank" >www.loedige.de:www.loedige.de