PUCEST® screen linings for extreme stresses

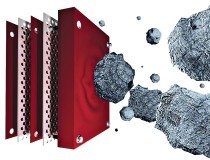

Known for its innovative wear protection products, PUCEST® protect has come up with highlight in its new generation of screen linings. For the construction materials industry, it will become increasingly important in future to reduce noise emissions. Noise is a nuisance for the employees at the workplace but also for the environment of the plant. Despite ever stricter environmental regulations, noise levels remain very high on account of the technology used. Costs for noise control must be taken into account. The most effective noise control would be to reduce noise emissions directly where the noise is generated. This is where the new generation of screen linings comes in, thanks to the noise-suppressing properties of the PUCEST® material combatting the generation of noise.

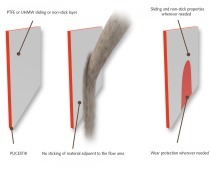

The screen linings demonstrate their strengths in extreme application conditions, for example in heavy-duty prescreening. Here, in particular. it is possible to lower noise levels substantially and save on costs for passive noise control. With the combination of highly wear-resistant PUCEST® with wear steel plate, it is possible to maximize flexibility while ensuring stability. Depending on requirements, they can be equipped with different perforated plates such as slotted plates, round-holed plates or hexagonal-hole plates.

Following one successful conversion to the new screen linings at a dolomite quarry, the feedback was positive – at a dolomite quarry, PUCEST® screen linings were installed as round-hole and slotted screens upstream of the jaw crushers. In addition to the wear protection, the customer especially praised the reduction in noise.