No shut down

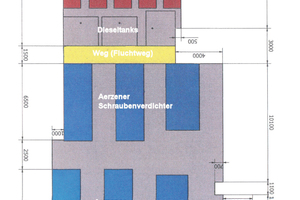

External compressed air emergency supply for a briquette factorySummary: This job bordered on achieving the impossible. In the central compressed air station of briquette factory Wachtberg in Frechen, near Cologne, part of RWE Power AG, repairs were to be performed. Temporarily, the compressed air station and the corresponding electrical distribution station had to be completely shut down. Nevertheless the compressed air supply should not be interrupted – particularly when you have a total delivery volume of 282 m³/min. But there was a solution: the temporary supply of the entire factory by an external rental station from Aerzen International Rental B.V. in Duiven (Netherlands), a subsidiary company of AERZEN near Hamelin. This rental station not only comprised six oil-free compressing screw compressors, but with five additional diesel driven generators also generated the necessary electrical energy for their operation.

At the Frechen site RWE Power AG process every year in a production around the clock 5.15 million tons of crude lignite into about 900 000 tons of pulverised lignite and 1.1 million tons of briquettes. In a second operational area the company’s own power plant produces 0.983 terawatt hours of electrical energy every year using briquetting carbon (B-carbon). For the 24-hour-production of both areas an uninterrupted compressed air supply is a must. The compressed air for the entire site is generated in a central station assigned to the power station by three oilfree compressing, speed-controlled...