The new generation of bucket crushers and screeners

bauma 2013 set the scene for brothers Alexander and Dominik Hartl to inform the crushing and screening world about their new venture as well as to introduce their entire product range publically; it consists of no fewer than eight different bucket crushers and screeners, complete with value-adding options. The brand name HARTL CRUSHER stands for a high-value, innovative range of products that combines over 40 years’ experience and innovation in the field of rock crushers and screeners produced by the Hartl family. By applying their unique technology to an extremely robust structure, they have integrated a jaw crusher into the form of an excavator bucket that guarantees high performance and reliability in the field of crushing and separation of natural stone and recycling material on site. Low running costs and environmentally friendliness are key words and formed an integral part of the design process.

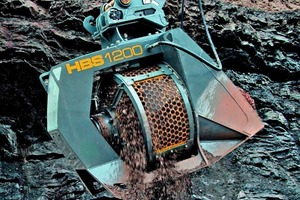

The bucket crusher that Hartl has developed is a top-quality, sturdy jaw crusher that can be mounted on and connected to an excavator (or similar machine) by means of a quick coupling system (Fig. 1). The crushing and screening units are powered by the excavator’s hydraulic circuits. Thanks to the unique Hartl “QUATTRO” movement, these crushers deliver a very high average performance rate with minimal wear, and a quality cubical end product with a minimal percentage of oversized material. The movement of the swing jaw plate is different to conventional crushers, which have a parallel motion. The Hartl system generates an aggressive figure eight motion that allows crushing to begin high up on the jaw faces and also creates a post-crush in the lower section of the crusher chamber as the material leaves the crusher. The result is a constant high quality, cubical material. Independent laboratory tests confirm that the HARTL design combined with the “fourfold” jaw movement results in up to 30 % less flaky end product when compaired to “double” jaw movement systems.

Their innovative construction concepts, truly modern production technologies and the exclusive use of tried and tested quality components, have resulted in a highly durable top-quality product that users find easy to maintain and service. Streamlined form and impressive design provide for the smooth intake of stones and materials, and ensure that the bucket crushers are instantly recognisable as typical Hartl products. April was the start of these products being exported to over 65 countries around the globe through a dedicated and highly motivated dealer network, most of whom have been involved with the HARTL family for many years.

As an absolute first in the industry, Hartl has now opened an Online Shop, that offers customers the opportunity to purchase all the replacement parts, options and additional products they require for their HARTL CRUSHER or HARTL SCREENER (Fig. 2) – 24 hours a day. The HARTL PARTS FINDER ensures that customers always locate the correct part, even if they do not have their maintenance book or spare-parts catalogue at hand. They can track their order and its delivery status online at any time through the Tracking System – from order to delivery. Customers can also find visual instructions for mounting and servicing their products correctly – just a click away! The investment in a central depot ensures that spare parts are generally available promptly.

With this new generation of bucket crushers and screeners Hartl is offering operators in material processing industries a solution for a flexible, mobile and economical crushing and separating solution. All this with minimal demand on space, transport and time. With Hartl equipment new business opportunities open up for all excavator owners wanting to grow their businesses by accessing the world of recycling quickly and with minimal capital investment.