NLMK Clabecq s.a.

NLMK Clabecq has increased the pace of its developments in Quenched and Tempered steels in order to propose wider ranges of thickness and grades. During the year 2013, the Belgian mill specialized in thin and large steel plates will come on the market with superior grades for Quard, its abrasion resistant steel and Quend, its high yield strength steel. It will allow to complete the range of adequate solutions to heavy machinery manufacturers. Thanks to the major technological developments & process throughout the production chain and the experience gained over the past year, the mill is speeding up its development planning for 2013, in order to finalize the industrial production of the Quard 500 and the Quend 960.

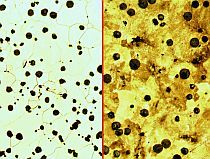

On the one hand, very hard wear resistant steels with a nominal hardness of 500 Brinell are used in mining and quarrying applications highly exposed to abrasion. NLMK Clabecq plans to deliver them this year in a thickness range between 4 and 40 mm, covering an important part of the market needs.

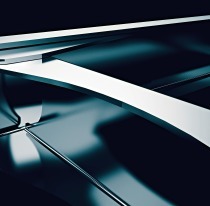

On the other hand, its steel with a minimum yield strength of 960 MPa, commercialized under the name of Quend 960, is expected to be launched in the coming weeks. A typical application for this very high quality steel grade is the telescopic arm of mobile cranes. NLMK Clabecq’s abrasion resistant steels and high yield strength steels have passed all the cutting, bending, machining and welding tests with success. To explain these positive results, users all raise as differentiating points the superior surface finish, tight thickness tolerances, excellent flatness and consistent homogeneity. These characteristics are the direct consequence of the layout of the NLMK Clabecq rolling line (a unique combination between a four-high rolling mill and a 4-stand continuous finishing mill) and of the performance of the new Quenching & Tempering (Q&T) unit.

The new Q&T line of NLMK Clabecq, an investment of 100 million Euro commissioned in 2011, is equipped with the latest heat treatment and leveling technologies. It has been tailor made by the most renowned suppliers with the expert advice of Q&T specialists. It makes it possible to optimize the control of key parameters like processing temperature and type of cooling. The quenching and the tempering of rolled plates are performed to modify the internal structure of steel, giving the mechanical properties required in function of the application (hardness, yield strength, tensile strength, elongation, ...). Using two separate levelers, NLMK Clabecq is able to supply steels with superior flatness to the highest standards (beyond the EN 10029 S-Class). With an expected production rate exceeding 200 000 t/year at full capacity, NLMK Clabecq already ambitions to produce up to 100 000 t of Q&T steel plates in 2013.

Hall A6; Stand 404