NETZSCH-Trockenmaltechnik GmbH

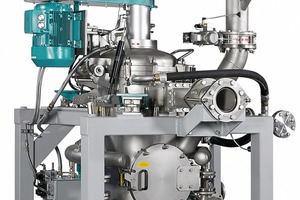

With the CGS 50 Fluidized Bed Jet Mill, NETZSCH will present a state-of-the-art solution for virtually contamination-free finest grinding of extremely hard and/or temperature-sensitive products, amongst other things suitable for recovered carbon black applications. In this model, the energy required for size-reduction is provided exclusively by gas jets, thus eliminating all wear on grinding tools.

Contamination-free grinding is also the main feature of the CSM 260 Ceramic Classifier Mill which will also be exhibited in Nuremberg. This proven system combines an impact grinding tool with an integrated dynamic air classifier. As all product-contacting parts are solid ceramic this machine is extremely well-suited for grinding raw materials for the manufacture of batteries.

A further NETZSCH exhibit at the Powtech will be the rapidly-running CONDUX® 220 CP Fine Impact Mill, which is designed for dry-grinding diverse products with a hardness measured on the Mohs scale of up to 3 – 3.5. This version of the CONDUX® machine achieves high finenesses (< 30 μm) and an exact upper particle size limit with its easy-clean and low-maintenance system. Unlike conventional classifier mills which have two drives, grinding disc and classifier wheel are fixed firmly to each other and are both driven by the same drive motor. In addition to this, a variable adjustment of the separation limit can be carried out by simply adjusting the classifying height.

The SPHERHO® SDA 1 is a very special innovation which also awaits visitors to NETZSCH´s booth. This is the laboratory version of the SPHERHO® Agitator Bead Mill which was presented at last year‘s Powtech. This machine was specially developed in cooperation with one of our partners drawing on the advantages of the SPHERHO® for dry-grinding mineral and ceramic materials, but either on a laboratory scale or for producing very small amounts. Like the larger version, the SPHERHO® SDA 1 achieves very high finenesses and high throughput capacities but at the same time has a low specific energy consumption.

Hall 4a-223