More flexible organisation of construction site processes with mobile stackers

The MOBIBELT stackers are available in three sizes and designs. The mobile stacker MOBIBELT MBT 20 has a crawler chassis and a belt length of 20 m. With the MBT 24, KLEEMANN also offers a further stacker with a crawler chassis and a length of 24 m. With a conveyor belt length of 15 m, the MBW 15 is the smallest in the portfolio and can be moved with a tractor to any work site. Depending on the construction site, the matching MOBIBELT stacker can be used and the logistics can thus be optimised on site. Three versions demonstrate the process in detail.

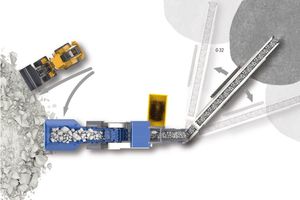

Application case 1: Operation with wheel loaders and mobile stacker

In example one, the material is loaded by a wheel loader and then cleared away by a mobile stacker. This constellation is often used in different natural stone applications with homogeneous feed material but it is also suitable for the processing of demolished or cut asphalt. If work is carried out with a wheel loader and mobile stacker, only one operator is required and lorries do not need to be loaded directly after the crushing and screening process. This makes a very lean construction site process possible.

Application case 2: Operation with excavator and mobile stacker

In this concrete case, the material is loaded by a backhoe excavator and then cleared away by a mobile stacker. This process can achieve very high daily outputs in recycling and natural stone applications because clearing of the stockpiles is not required. Provided that no prescreened material has to be discharged and that no lorries are to be loaded directly downstream of the crushing and screening process, this is the most cost-effective variant.

Application case 3: Operation with excavator, wheel loader and stacker

In the third application example, a backhoe excavator loads the material, mobile stackers clear it and a wheel loader loads the processed product. This is one of the most popular constellations in recycling and natural stone applications because, in comparison to the other variants, it makes the highest daily output possible. This process is recommended, in particular, if lorries directly downstream of the crushing and screening process are to be loaded.