Mobile container system - an individual and mobile process solution

Complete system solutions tailored to the customer’s requirements can be realised with this concept. A number of mill systems can be linked together and installed in several containers. All production and control steps take place inside the container. The customer thus receives an individual and mobile process solution – Made in Germany.

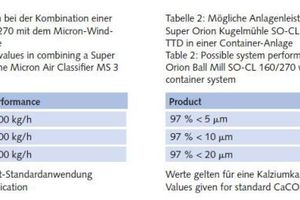

The plug-and-play system guarantees fast commissioning. After delivery to the customer, the container system is ready for operation within two to three days – and the reverse is also true, i.e. it can be dismounted just as quickly. This means that further investment measures such as building a new production hall are no longer necessary. Besides the fixed and variable costs, the initial investment costs of a container system are thus relatively low. And dependent on the country, the mobile design means that no permits are required. Possible system performance values are the result of the system combination. For example, if the Super Orion Ball Mill SO-CL 160/270 is combined with the Micron Air Classifier MS 3 in a container system for the production of calcium carbonate fillers, a throughput rate of 1000 kg/h at 97 % < 15 µm can be achieved. Much finer qualities down to D97 > 5 µm are possible in the combination with a 315 TTD at a throughput rate of 300 kg/h. Hosokawa Alpine has thus designed a mobile container system that really pays off.

Hall 4A / 233

//www.hosokawa-alpine.com" target="_blank" >www.hosokawa-alpine.com:www.hosokawa-alpine.com