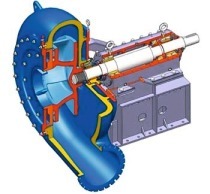

Manufacturing state-of-the-art suction dredgers and upgrading older models

Since its establishment in 2019, Dredgers & Pumps GmbH has made a name for itself in the manufacture of modern suction dredgers and the modernization of older, existing suction dredgers. In recent years, a series of high-performance, energy-efficient suction dredgers have been introduced to the market. The suction dredgers are optimally adapted to the existing operating conditions after technical clarification and analysis of the geological conditions. In this way, it is possible to keep the energy requirement per ton of material conveyed as low as possible with innovative equipment such as frequency-controlled dredge pumps, suction and ladder winches, vacuum flaps etc. Electric drives are used as IE4 versions and have an efficiency of min. 96 %, also contributing to cost reduction. The scope of services includes automatic suction dredger controls, as well as GPS-based excavation controls and unmanned controls for suction dredgers.

The above-mentioned components and ongoing technical development ensure that the suction dredger remains an efficient piece of equipment for extracting gravel and sand in a cost-effective manner, even in times of steadily rising energy costs. Thanks to the modular design of the suction dredgers, exact tailoring to specific customer requirements is easily possible. In addition to hardware, the holistic approach of Dredgers & Pumps also includes comprehensive digitization, which goes under the heading of “Suction dredger as a service”. After all, a modern extraction machine must also always be at the forefront of innovation. In concrete terms, this means that the suction excavator remains under control at all times via digital remote maintenance and monitoring. Operating data is permanently recorded and evaluated, so that undesired deviations from normal operation can be detected immediately and eliminated during operation by the manufacturer’s specialists. This process optimization ensures that the suction excavator operates at the highest possible efficiency at all times.

The know-how gained in the design of new suction dredger systems is also implemented in the renovation of existing suction dredgers. For example, older suction dredgers have been rebuilt for some well-known operators in such a way that several thousand euros in energy cost savings per month could be realized at the same pumping rates. If older suction dredgers are in good technical condition, these conversions can be carried out with relatively simple means and help to make old suction dredgers fit for the future. Even old models have a future in times of high energy prices.