Increased productivity of high powered belt conveyors

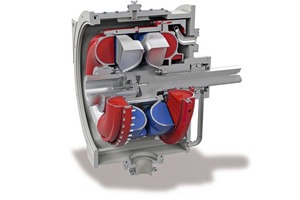

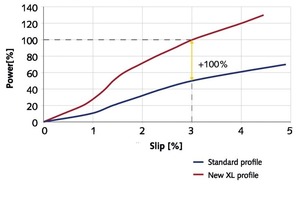

Developed especially for the drives on open-pit mining belt conveyors, the latest fluid coupling technology from Voith – the TurboBelt 780 TPXL (Fig. 1) – provides a lot of benefits. Thanks to the innovative XL blade wheel profile, the TurboBelt 780 TPXL coupling transmits twice the power previous couplings of similar size could achieve. It is designed for 6- and 8-pole induction motors operating at speeds of 900 to 1200 rpm. The start-up with precisely-controlled introduction of torque not only protects the belt, but also the entire driveline. Even overloaded belt conveyors are started reliably. Start-up times of up to several minutes can be individually set in the control system.

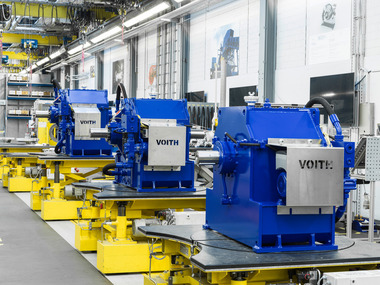

In May 2012, the initial start-up of this new fluid coupling was in one of the biggest sea terminals in northern Brazil, where iron ore is shipped worldwide (Fig. 2). In order to handle the increasing amount of iron ore, the operating mining company decided to install three TurboBelt 780 TPXL couplings in the drives of a 1451 m long conveyor. The couplings assure smooth operation and avoid unscheduled downtimes of the belt conveyor. As the conveyor transports around 10 000 t of iron ore every hour, its reliability has high priority for the mining company. When combined with reliable mechanics, the hydrodynamic TurboBelt 780 TPXL coupling provides extremely high system availability of up to 99.8 % (Fig. 3).

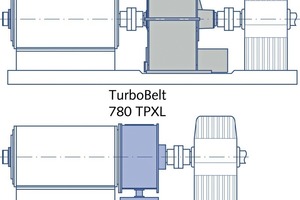

The maintenance efforts can be reduced to a minimum as the hydrodynamic power transmission is completely wear-free. Compared with traditional couplings, the TurboBelt 780 TPXL requires only half as much installation space and is also significantly lighter (Fig. 4). This has enabled a simple and quick installation and alignment in the Brazilian sea terminal. Altogether, the new TurboBelt 780 TPXL couplings raise the productivity and profitability of the belt conveyor. Besides the couplings, the mining company benefits from a customized package also delivered by Voith.

In order to operate the conveyors always in the most efficient way Voith offers not only couplings, but also optimal drive solutions based on the customer’s needs. The drive package solutions include the drive hardware, PLC controller and supervision of installation as well as commissioning.