Increased availability and productivity in gold mine

In the “Paracatu” gold mine belonging to the Canadian based mining company Kinross Gold Corporation, Siemens started up the world’s first ore-grinding mill with the Frozen Charge Shaker function in December 2008. With the help of this solution, which is integrated in the Simine Mill GD gearless mill drive, charge that has become firmly attached (frozen) to the inside wall of the mill can be removed as required. This prevents the mill from being damaged as a result of charge falling down in an uncontrolled manner and also, simultaneously, reduces maintenance times considerably. Given that production is worth thousands of US$/h, a production loss of several million US$ incurred for each maintenance cycle can be avoided.

When maintenance has to be carried out, grinding mills used in mining installations have to be shut down for several hours or days. In this time, the remaining mill charge can easily solidify, firmly attaching itself to the wall of the mill. This is called “frozen charge”. When the mill is started up again, there is a danger that the frozen charge will not detach itself from the mill wall immediately but will initially be lifted up by the mill and then fall down from a great height. The resulting damage to the mill can be severe. Gearless mill drives of the type Simine Mill GD come with a Frozen Charge Protection function that detects firmly attached charge in good time and switches off the mill. This prevents damage being done but does not automatically eliminate the frozen charge. Frequently, the material does not break up and remains stuck to the wall of the mill. This is why it used to be necessary to apply labor-intensive mechanical means to remove the firmly attached charge. This lengthens the down times by hours or days and can lead to production outages costing several million US$.

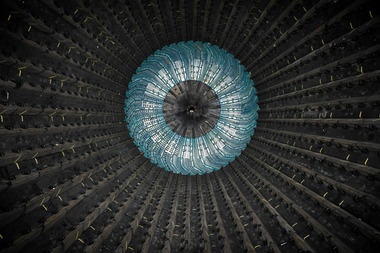

With the help of the Frozen Charge Shaker function integrated in the Simine Mill GD system, deposits can be loosened by causing the mill to move appropriately. To do this, the operating personnel initiate the Frozen Charge Shaker mode of the mill drive at the local control desk. The mill shell is then tilted at an angle so that any material that falls cannot damage the insides of the mill. Specific alterations of the grinding tube’s acceleration and direction of rotation loosen the charge that is stuck on, thus causing it to be detached from the wall of the mill. The motor is the same one that is used for grinding. The Frozen Charge Shaker avoids interruption of production for removal of a solidified charge attached to the mill shell.

The “Paracatu” open-cast gold mine operated by the mining company Kinross Paracatu belongs to the Kinross Gold Corporation and is the largest single gold mine in the world in terms of ROM processing. The mining site is near the historical gold-digger city of Paracatu, around 220 km to the south-east of the capital, Brasilia. A 38-foot SAG (Semi Autogenous Grinding) tube mill is used for crushing the ore. Siemens had received the order to supply a Simine Mill GD gearless drive system with an output of 20 megawatts and the Frozen Charge Shaker function in 2006.

www.siemens.com/industry-solutions