In good condition?

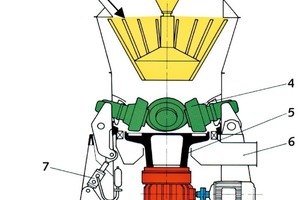

Condition Monitoring increases availability of vertical millsSummary: Limestone, clinker or coal: the cores of vertical mills that crush such materials are the drives. An operator increases availability by relying on an integrated condition-monitoring system right from the commissioning. Thus, early failure detection and, in combination with remote service, even trouble shooting is possible – and maintenance costs can be reduced.

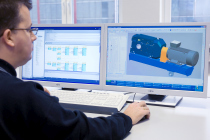

Condition Monitoring Systems:

rather integrating than retrofitting

The use of Condition Monitoring Systems (CMS) is state of the art in modern industrial plants. However, they are still retrofitted in already existing plant components, since many companies spare investment costs when installing new plants or they do not consider necessary the use of CMS during the warranty period. Apart from the general advantages, even disadvantages occur, such as increased investment costs, interface problems or poor accessibility of installation sites. Thus, retrofitting of a main drive, for instance, is...